23

3062880_0910

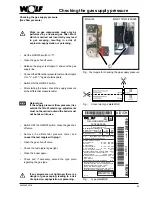

Checking the gas supply pressure

(Gas flow pressure)

• Set the ON/OFF switch to "0".

• Open the gas shut-off valve.

• Release the plug at test nipple

and vent the gas

supply line.

• Connect the differential pressure tester at test nipple

to "+", with "-" against atmosphere.

• Switch ON the ON/OFF switch.

• After starting the boiler, check the supply pressure

at the differential pressure tester.

Work on gas components must only be

performed by a licensed gas fitter. Work

which is carried out incorrectly may lead

to gas escaping, resulting in a risk of

explosion, asphyxiation or poisoning.

Checking the gas supply pressure

• Switch OFF the ON/OFF switch. Close the gas shut-

off valve.

• Remove the differential pressure tester and

re-seal the test nipple with plug

.

• Open the gas shut-off valve.

• Check the test nipple is gas-tight.

• Close the boiler again.

• Check and if necessary amend the type plate

regarding the gas type.

Natural gas:

If the supply pressure (flow pressure) lies

outside the 18 to 25 mbar range, adjustments

must not be carried out and the boiler must

not be taken into use.

NB

If any screws are not tightened, there is a

danger of gas escaping, leading to a risk

of explosion, asphyxiation or poisoning.

Fig.: Test nipple for checking the gas supply pressure

MGK-170/210/250/300

MGK-130

Gas-Brennwert-Heizgerät

1234567890

Herstellnummer

Nennwärmebelastung

Heizen

Nennleistung

Heizen 50/30°C

Heizen 80/60°C

Netzanschluß

Q = 28 - 160 k

W

P = 30 - 167 k

W

P = 27 - 156 k

W

90°C

230V ~ 50 Hz

280 W

Elektrische Leistungsaufnahme

Schutzart

Max. Vorlauftemperatur

Max. Betriebsdruck Heizkreis PMS = 6 bar

IP40

Wasserinhalt Heizwärmetauscher

087511121234567890

08

75

11

12

12

34

56

78

90

875

111

2

Art

.-N

r.

CE-0063BQ3805

A/D/CH

123

456

789

0

He

rst.

-Nr

.

08

Typ MGK-170

NO

x

Klasse

5

Kategorie

- G20 - 20 mbar

Bestimmungsland

Eingestellt auf

B23, B33, C33, C43, C53, C83

C63 gem. Montageanleitung

15 l

W

armwasser

Q = 28 - 160 k

W

Abgaswertegruppe nach DVGW 635

G

52

Art

8751156

06/08

DE/AT/CH

Der Kessel darf nur in einem Raum

installiert werden, der die maßgeblichen

Belüftungsanforderungen erfüllt.

Lesen Sie die Montage- bzw.

Betriebsanleitung bevor Sie den Kessel

installieren bzw. in Betrieb nehmen.

MG

K-1

70

E/H

II2ELL3P

DE

II2H3P

AT

2H

2E

CH

I2H

2H

Fig.:

Type plate MGK

Fig.:

Conversion type plate MGK