28

3062880_0910

B) CO

2

adjustment at the lower load

(soft start)

• Restart the gas condensing boiler by pressing the

"Reset button".

• Check and if necessary correct the CO

2

content

approx. 30 s after burner start using the CO

2

tester,

by fine adjusting the

zero point adjusting screw

in

accordance with the table. Make this adjustment within

120 s of the burner start. If necessary, repeat the start

phase for setting procedures by pressing the reset

button.

•

Turn clockwise - raises CO

2

content

•

Turn anti-clockwise - lowers CO

2

content

Appliance open

(without casing) at

lower

load

Natural gas H

9.0% ± 0.2%

Changing the gas type / CO

2

settings

A) CO

2

setting at the upper load

(emissions test mode)

• Undo the four screws from the front casing and

remove the casing.

• Remove the screw from the "flue gas" test port.

• Insert the test probe of the CO

2

test instrument into

the "flue gas" test port.

• Turn the temperature selector to

"Emissions test"

.

(Illuminated status indicator ring flashes yellow.)

• Check the CO

2

content at full load, and compare the

actual values with those in the table below.

• Correct the CO

2

setting as required using the

gas throughput adjusting screw

on the gas

combination valve in accordance with the table.

• Turn clockwise - lowers CO

2

content

• Turn anti-clockwise - raises CO

2

content

• Terminate the emissions test mode by returning the

temperature selector to its original position.

Fig.: Flue gas test at the integral test port

Test port, flue gas

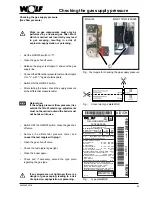

Fig.: Gas combination valve

Gas throughput adjusting screw (under cover)

Allen screw 3 mm for the MGK-170 - MGK-300)

Slotted screw for the MGK-130

MGK-170/210/250/300

MGK-130

Appliance open

(without casing) at

upper

load

Natural gas H

9.2% ± 0.2%

Fig.: Gas combination valve

Zero point adjusting screw, Tx40 Torx (under the

cover)

MGK-170/210/250/300

MGK-130