MAINTENANCE

QUICK 98560 09/20/99

4-1

GENERAL

The

QUICK©

has been designed with many

maintenance free features. Except as noted, all

bearings are permanently lubricated and sealed. All

friction points use bushings which do not require

lubrication. Keeping the equipment clean is the

primary preventative maintenance. With the

exception of the brush motors, vacuum motors, and

the main drive motor all exposed areas may be

washed without damage to the machine. A few steps

can be taken by the user in order to provide trouble

free service. The following explanations are

guidelines to follow for user service.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

DIRECTIONAL CONTROL SYSTEM

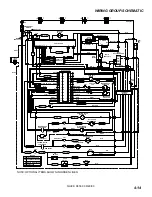

(Refer to the “Electrical Component Group” in the parts manual)

The directional control system controls the direction

and speed of the machine. The system is made up

of the directional pedal, the electronic throttle, the

controller and the traction motor. The controller,

located in the electrical compartment, can only be

serviced by trained personnel.

DIRECTIONAL CONTROL PEDAL ADJUSTMENT

(Refer to the “Pedal Group” in the parts manual)

The directional pedal is designed to prevent driver

fatigue. The pedal should require little effort to

operate. The complete assembly can be mounted in

two different positions to suit the individual. If a

different pedal position is preferred follow the

directions below.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

1. Disconnect batteries from machine.

2. Locate the two bolts securing the pedal mount to

the floor plate.

3. Loosen the rear bolt and remove the front bolt.

4. Move assembly to alternate position.

5. Reinstall and tighten bolts.

SCRUB HEAD

(Refer to the “Scrub Head Group” in the parts manual)

The scrub head consists of two rotary type scrub

brushes, drive motors, self-adjusting side squeegee,

and splash skirt. The scrub head is factory adjusted

and has machine controlled down pressure

adjustment. The operator can select one of four

different down pressure settings on the touch control

panel. There are no mechanical adjustments to be

made by the operator. The hex drive hub allows

brushes to follow irregularities and changes in floor

without losing contact with floor.

NOTE: Do not use a pressure washer to clean the

Scrub Head. Use tap pressure only. Care must be

taken so that water is not directed in brush motor air

intakes.

SCRUB BRUSHES

NOTE:

All original equipment brushes are equipped

with “Perform Alert©”. This feature will tell the

operator when it is time to replace the scrub

brushes. “Perform Alert©” brushes have pre-trimmed

bright yellow tufts. When the tufts in the scrub brush

wear to a length equal to the yellow tufts, the scrub

brushes should be replaces.

There are five different types of brushes available to

cover applications from cleaning heavily soiled floors

to polishing. A pad driver is also available to take

advantage of the many cleaning pads on the market

and further add to the flexibility of the

QUICK©

.

Please refer to the following to assist in selecting the

proper brush or pad for the work at hand.