Page 12

Installer’s Information Manual

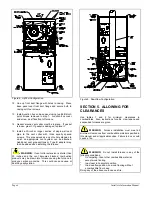

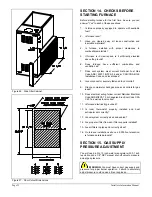

You must connect furnace to a listed chimney or vent

complying with a recognized standard or a suitably sized,

constructed and lined masonry chimney. Chimney lining

method and material must comply with local requirements.

Use corrosion-resistant material meeting nationally

recognized standards for vent construction.

This furnace must not vent into an unlined-masonry

chimney or an unlined-concrete chimney and must not

single appliance vent into a tile-lined chimney. However,

this furnace may be common vented into a tile-lined

masonry chimney provided (1) the chimney is currently

serving at least one drafthood equipped appliance and (2)

the vent connectors and chimney are sized in accordance

with the appropriate vent table.

WARNING

: Select appropriate venting materials

and clearances. Inadequate vent or chimney could allow

combustion products to collect in building, resulting in fire,

nausea or death by asphyxiation.

WARNING

: Do not use unlined masonry

chimneys. These increase risk of condensate formation,

which may cause chimney to deteriorate, allowing

combustion products and condensate to collect in building.

Multistory and common venting with other Category I

appliances is permitted. The venting system must be in

accordance with the National Fuel Gas Code ANSI

Z223.1/NFPA 54 and/or current CAN/CGA B149 Installation

Codes, local codes and approved engineering practices.

Vent this furnace separately from any appliance designed

to burn solid fuel, such as wood or coal. If a fireplace

chimney flue is used to vent this appliance, the fireplace

opening must be permanently sealed.

Avoid over-sizing furnace for your application. Select a

furnace model with a rated heating output close to the

calculated heating load. This extends the firing period,

decreasing the potential for condensate formation in the

vent.

The designer must consider the building's orientation,

answering two questions: Will the vent terminate outside

the building where its operation could be adversely affected

by winds? Could any adjacent buildings adversely affect

vent operation? Allowing for these factors can reduce the

possibility of down draft conditions.

If your local experience indicates possible condensation

problems, provide for draining and disposal of venting

system condensate.

VENT SIZING AND INSTALLATION

Proper vent size can be determined from these instructions

and "Venting Tables For Category I Venting" included as an

addendum to these instructions, the National Fuel Gas

Code ANSI Z223.1/NFPA 54 and/or current CAN/CGA

B149 Installation Codes. Venting tables include instructions

for single appliance venting and multiple appliance

(common) venting.

Refer to venting tables for correct size vent. An undersized

vent cannot adequately carry all combustion products

outdoors. An oversized vent will not heat up rapidly enough

to avoid condensation.

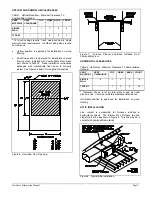

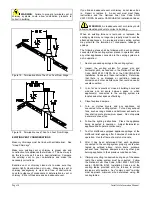

Vents and chimneys usually extend vertically with offsets

not exceeding 45 degrees from vertical. Consider vent pipe

runs more than 45 degrees from vertical as horizontal runs.

Include their length in the total horizontal run.

Vent height must be a minimum of five feet for Category I

vent systems. Minimize vent connector horizontal runs to

the extent possible for best performance. Horizontal

portions of the venting system must be supported at each

joint using hinges, straps or equivalent to prevent sagging.

Slope horizontal portions upward from furnace at least 1/4

inch per foot.

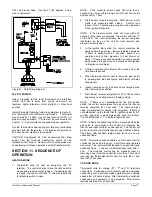

Sometimes the horizontal distance from the furnace to the

vent or chimney is already given. This is known as the

horizontal vent connector run. The vent or chimney height

is also usually given as is the Btu per hour input of the gas

appliances served by the vent. Check these parameters to

be sure the venting system will work. Use venting

addendum, these instructions, part 7 of current National

Fuel Gas Code ANSI Z223.1/NFPA 54 and/or CAN/CGA

B149 Installation Codes. Use vent capacity tables in

venting addendum to check existing or new vent sizes for

Category I furnaces.

Install vent materials following their listing terms,

manufacturer's instructions, these instructions and local

codes.

A gas vent passing through a roof must extend through roof

flashing, jack or thimble. It must terminate above roof

surface.

Designer and installer must provide an appropriately sized

common vent for all appliances connected to it. See

venting addendum for single appliance venting and multiple

appliance (common) venting. For multistory installations,

refer to current National Fuel Gas Code ANSI Z223.1/NFPA

54 and/or CAN/CGA B149 Installation Codes.

VENT CONNECTORS

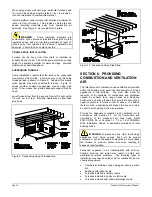

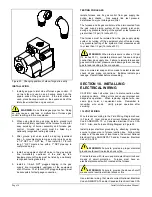

Vent connectors must be made of listed single-wall or Type

B double-wall components. They must be thick enough to

withstand physical damage and be readily accessible for

inspection, cleaning and replacement.

Use Type B vent connectors in or through attics, crawl

spaces, or other cold areas. Install thimbles that meet local

codes when vent connectors pass through walls or

partitions of combustible material.

Keep vent connectors as short as possible by locating

furnace as close as practical to vent or chimney. Avoid

unnecessary turns or bends that create resistance to flow of

vent gases. Adding an elbow adds resistance.

You may increase vent connector diameter to overcome

installation limitations and obtain connector capacity equal

to furnace input. Make this increase as close as possible to

furnace vent collar, allowing for necessary adapters and

fittings. Do not increase vent size more than two sizes