Page 14

Installer’s Information Manual

WARNING

: Failure to properly terminate vent or

chimney systems could allow combustion products to

collect in building.

Figure 18. Termination More Than Ten Feet From Ridge.

Figure 19. Termination Less Than Ten Feet From Ridge.

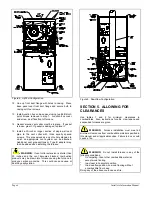

EXISTING VENT CONSIDERATIONS

Masonry chimneys must be lined with suitable liner. See

"Lined Chimneys".

Make sure existing vent or chimney is proper size and

construction for appliances that will use it. The best way to

do this is to size as if it were a new installation. Compare

the existing vent to your calculations and make the

necessary corrections.

Examine vent or chimney clean-outs to make sure they

remain tightly closed when not in use. Make sure vent or

chimney passageway is clear and free of obstructions.

Look for evidence of condensate or deterioration in vent or

chimney. Either of these means an inadequate vent.

If you find an inadequate vent or chimney, do not leave it as

is. Repair or replace it. A new vent must meet these

instructions and the National Fuel Gas Code ANSI

Z223.1/NFPA 54 and/or CAN/CGA B149 Installation Codes.

WARNING

: An inadequate vent or chimney could

allow combustion products to collect in building.

When an existing furnace is removed or replaced, the

venting system may no longer be properly sized to vent the

attached appliances. An improperly sized venting system

may promote the formation of condensate, leakage or

spillage.

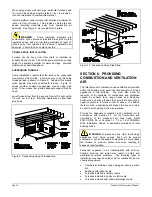

The following steps shall be followed with each appliance

connected to the venting system placed in operation, while

any other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in the venting system;

2. Inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the CAN/CGA B149

Installation Codes and these instructions. Determine

that there is no blockage or restriction, leakage,

corrosion and other deficiencies that could cause an

unsafe condition;

3. In so far as is practical, close all building doors and

windows and all doors between space in which

appliance(s) connected to the venting system are

located and other spaces of building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they shall operate at maximum speed. Do not operate

a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance shall operate continuously;

7. Test for drafthood equipped appliance spillage at the

drafthood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle;

8. After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-

burning appliance to their previous conditions of use;

9. If improper venting is observed during any of the above

tests, the venting system must be corrected. Follow

the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/or CAN/CGA B149 Installation Codes and the

venting tables provided with the furnace to correct

improper vent operation. Any "common vent" re-sizing

must approach minimum size determined using the

venting tables.