Page 26

Installer’s Information Manual

overlap the burner-mounting flange of the adjacent

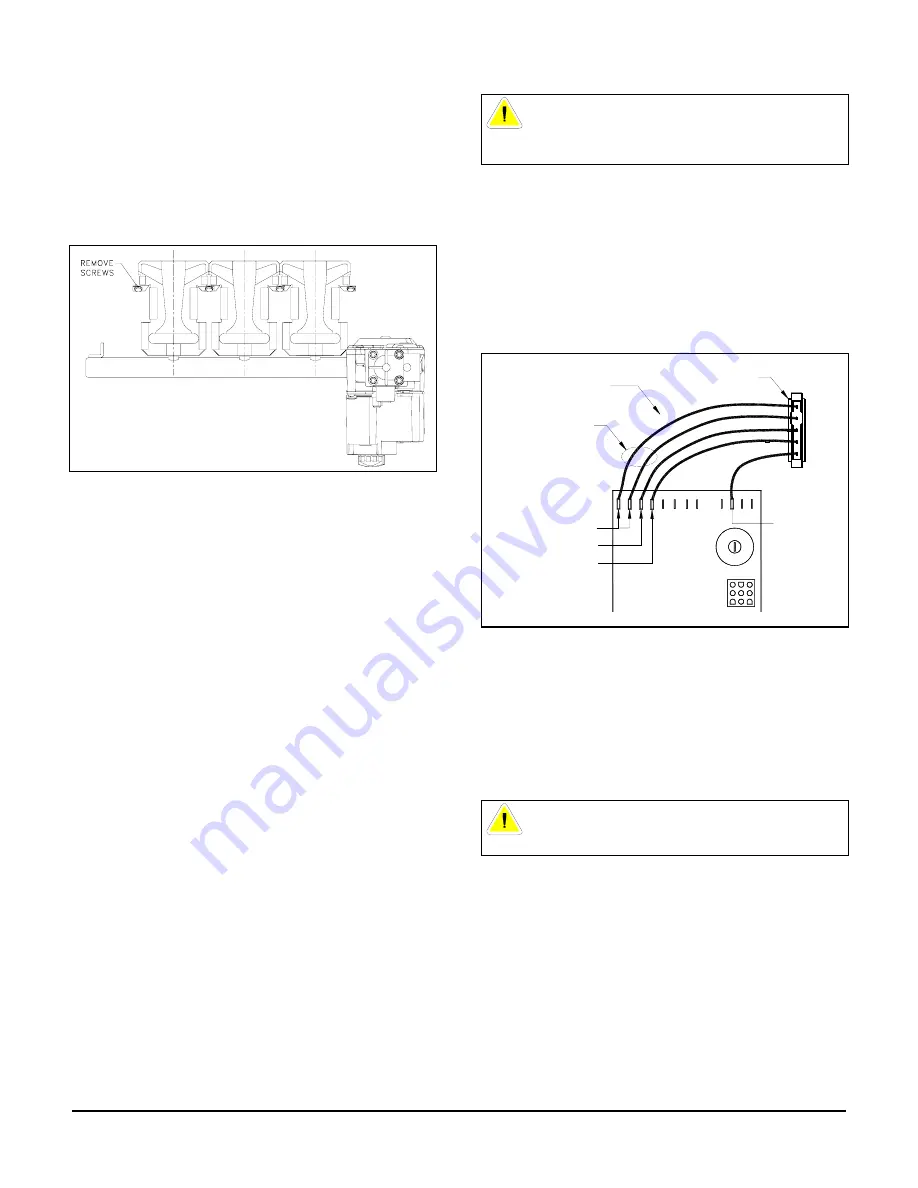

burner. See Figure 29.

6. Remove original gas orifices.

7. Carefully, hand thread new orifices into manifold. Do

not cross-thread. Tighten to torque of 50 inch-pounds.

8. Replace burners in reverse order, starting with the

burner closest to the gas control. Remember: burner-

mounting flange of burners farther from the gas control

overlap the burner mounting flange of the adjacent

burner.

Figure 29. Main Burner Removal.

9. Check burner carry-over alignment. Burner carry-overs

may touch but not overlap adjacent burner carry-overs.

Replace screws.

10. Turn gas control switch to “ON” position.

11. Open equipment shut-off valve in gas supply line just

ahead of furnace.

12. Set room thermostat to highest setting.

13. Turn on electricity at electrical disconnect switch

located next to furnace. Furnace will light.

14. Check for gas leaks using commercial soap solution

made for leak detection.

15. Check gas input following Section 17, "Checking Gas

Input Rate."

SECTION 21. ADJUSTING

BLOWER SPEED

Determine initial heating and cooling speeds in system

design stage. See Product Data Sheet for airflow data.

Depending on tests performed in following sections, you

may need to change blower motor speed.

CAUTION: Heating speed tap should not be reduced below

factory setting. Doing so may result in inadequate air

circulation, and could cause excessive air temperature rise

through furnace. This could cause a high-temperature limit

switch to cycle burners on and off, reducing furnace

efficiency and shortening life of heat exchanger and blower

motor.

Follow this procedure:

1. Turn off electricity at electrical disconnect switch

located next to furnace.

WARNING

: To prevent electric shock, turn off

electrical power to furnace before changing blower motor

speed.

2. All models have these four motor speed designations:

High Speed (HI)

Black wire

Medium High Speed (MH)

Blue wire

Medium Low Speed (ML)

Yellow wire

Low Speed (LO)

Red wire

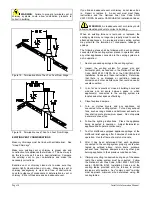

3. To change cooling speed, move the desired motor lead

to the terminal marked 'COOL' on the Control. See

Figure 30. Initial factory setting for cooling is high

speed (black wire).

Figure 30. Main Blower Speed Selection.

4. To change the heating speed, move the desired motor

lead to the terminal marked 'HEAT' on the Control.

See Figure 30. Factory setting for heating is listed in

Table 10. Heating speed should not be reduced below

factory setting.

5. Connect the two unused motor leads to the terminals

marked "UNUSED MOTOR LEADS" or “PARK” on the

Control. See Figure 30.

WARNING

: Failure to properly terminate unused

motor leads could cause electrical shock.

6. Turn on the electricity at electrical disconnect switch

located next to furnace.