Installer’s Information Manual

Page 5

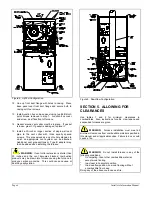

Provide ample space for servicing and cleaning, and

around air openings into the combustion chamber.

Location must allow 30 inches minimum front clearance for

service.

You may install furnace on non-combustible flooring or for

upflow or horizontal installations on wood flooring. A

combustible floor base, available from the manufacturer, is

required for downflow furnace installation on wood flooring.

See Section 5, "Allowing For Clearances."

Install the furnace so all electrical components are

protected from water.

Install the furnace level.

When the furnace is in a repair garage or inside the heated

space, exhaust fans can adversely affect its operation.

Exhaust fans in kitchen, bathrooms, clothes dryers or

anywhere within heated space increase combustion and

ventilation air requirements. This is because exhaust fans

reduce the amount of combustion and ventilation air

available to the furnace. A fireplace also reduces amount

of combustion and ventilation air.

WARNING

: You must allow for these reductions

or there could be inadequate combustion and ventilation

air. This could cause nausea, death by asphyxiation, or

fire.

Sufficient air must be provided to ensure there will not be a

negative pressure in furnace room or space. In addition,

there must be a positive seal between furnace and return

air duct to avoid pulling air from burner area.

When a cooling unit is installed with this furnace, the

furnace must be installed on the upstream side of the

cooling unit to avoid condensation in the furnace heat

exchanger.

When furnace is in a residential garage, it must be installed

so that the main burners are located no less than 18 inches

above the floor. Also, furnace should be protected from

physical damage by vehicles.

When furnace is in a public garage, airplane hanger, or

other building having hazardous atmosphere, install unit in

accordance with recommended good practice requirements

of the National Fire Protection Association, Inc. Consult

local code authorities for additional location requirements.

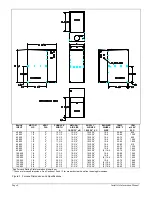

See Figure 3 for dimensions and specifications.

SECTION 4. CONVERSION TO

DOWNFLOW CONFIGURATION

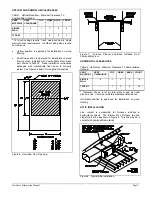

Most furnaces are shipped from the factory in the upflow

configuration with the vent collar extending out through the

top plate at the supply end of the furnace. In this

configuration, the furnace can be installed as an upflow

furnace or as a horizontal furnace on its left or right side.

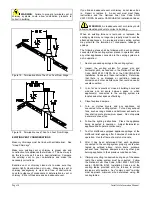

In the downflow configuration, the inducer assembly is

repositioned - locating the vent collar inside the furnace

vestibule near the manifold pipe. In this configuration the

furnace can be installed as a downflow furnace or as a

horizontal furnace on its left or right side.

Before starting the conversion, lay the furnace on its back

with the front door removed. Read the following

instructions all the way through and study the components

described. See Figure 4 for component identification and

location.

NOTE: If possible, decide on direction of gas entry now,

because the screws to change direction of the furnace gas-

control-inlet elbow are accessible during this conversion.

See Section 9, "Installing Gas Piping."

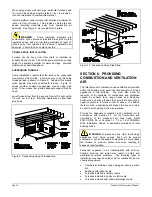

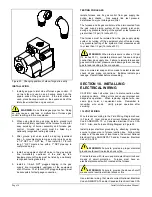

1. Remove the two junction box mounting screws and the

four top plate mounting screws. Save all screws.

Remove the top plate and front duct flange.

2. Disconnect pressure switch wires and inducer motor.

3. Remove and save ten screws from the inducer pan.

Do not drop screws into heat exchanger openings.

4. Lift inducer/pan assembly about 1/4 inch and tilt left

side up to clear top casing flanges.

5. Rotate inducer/pan assembly 180 degrees as shown in

Figure 5. Line up mounting holes and replace the ten

screws in inducer pan.

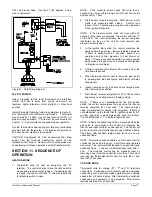

6. If nessessary, remove wire tie(s) from the excess

length of the wire harness containing the pressure

switch wires (blue and purple).

7. Re-connect pressure switch wires as follows. (Wires

are numbered on insulation near terminals).

a) Purple wire (#6) to pressure switch common

(C) terminal.

b) Blue wire (#5) to pressure switch normally

open (NO) terminal.

c) Route pressure switch wires around inducer

motor and away from hot flue box.

8. Re-connect inducer motor.

9. Replace wire tie in the same area such that wires do

not touch hot flue box or inducer pan.

10. Remove and save the four screws that secure base

panel to casing sides. Remove base panel.

11. Install top plate removed in step 1 in place of the base

panel. Secure with four screws. Vent collar is now

lined up with vent outlet hole in top plate.