6

b. Be either hard-wired or battery powered or both; and

c. Shall comply with NFPA 720 (2005 Edition).

3.

A product-approved vent terminal must be used, and if applicable, a product-approved air intake must be used. Installation

shall be in the strict compliance with the manufacturer’s instructions. A copy of the installation instructions shall remain with

the appliance or equipment at the completion of the installation.

4.

A metal or plastic identification plate shall be mounted at the exterior of the building, four feet directly above the location of

vent terminal. The plate shall be of sufficient size to be easily read from a distance of eight feet away, and read “Gas Vent

Directly Below”.

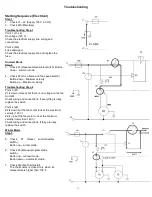

A. Clearance above grade, veranda, porch, deck or

balcony 12-inches (30 cm) minimum.

(3)

B. Clearance to window or door that may be opened 12-

inches (30 cm) minimum.

(3)

C. Clearance to permanently closed window (minimum 12-

inches (30 cm) recommended to prevent condensation

on window.

D. Vertical clearance to ventilated soffit located above the

terminal within a horizontal distance of 2 feet (60 cm)

from the centerline of the terminal 18-inches (46 cm)

minimum.

E. Clearance to unventilated soffit 12-inches (30 cm)

minimum clearance to vinyl soffit 36-inches (90 cm)

minimum.

F. Clearance to outside corner 12-inches (30 cm)

minimum.

G. Clearance to inside corner 18-inches (46 cm) minimum.

H. Not to be installed above a meter/regulator assembly

within 3 feet (90 cm) horizontally from the centreline of

the regulator.

(3)

I.

Clearance to service regulator vent outlet 6 feet (1.8 m)

minimum.

(3)

J. Clearance to non-mechanical air supply inlet to building

or the combustion air inlet to any other furnace 12-

inches (30 cm) minimum.

(3)

K. Clearance to a mechanical air supply inlet 6 feet (1.8 m)

minimum.

(3)

L. Clearance

(1)

above paved sidewalk or a paved driveway

located on public property 7 feet (2.1 m) minimum.

(3)

M. Clearance under veranda, porch, deck or balcony 12-

inches (30 cm) minimum.

(2),

(3)

Notes:

(1)

A vent shall not terminate directly above a sidewalk

or paved driveway which is located between two

single family dwellings and serves both dwellings.

(2)

Only permitted if veranda, porch, deck or balcony is

fully open on a minimum of two sides beneath the

floor.

(3)

As specified in CGA B149 installation codes (1991).

Note: Local codes or regulations may require different

clearances.

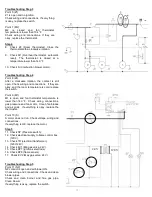

Figure 1

1 = Fixed/Closed

2 = Openable

V = Vent Terminal

A = Air

Supply