5

Installation

Installation should be done by a QUALIFIED SERVICE TECHNICIAN.

The furnace must be located on an outside wall.

Wall Installation

Minimum clearances from combustible materrials:

•

Unit to the top surface of carpeting, tile: 2-inches (50 mm)

•

Unit to back wall (0" to spacers): 0-inch (0 mm).

•

Vent to wall enclosure: 0-inch (0 mm)

•

Unit to sidewalls: 3.15-inches (80 mm)

•

Unit to ceiling: 10-inches (254 mm)

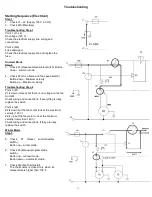

See Figure 1 showing clearance for installation of vent cap.

Leave at least three-feet in front of the wall furnace for

servicing and proper operation. The wall furnace must be

installed in such a way that the external casing can be

completely removed for servicing.

If there is a shelf above the furnace, it must be non-combustible. A minimum clearance of 12-inches (300 mm) is recommended

between the furnace and the non-combustible shelf above it.

Gas equipment installed in residential garages must be installed so that all burners and burner ignition devices are located not

less than 18-inches (460 mm) above the floor. Such equipment must be located, or protected, so it is not subject to physical

damage by a moving vehicle.

The vent terminal of this direct-vent furnace must be located at least 9-inches (230 mm) from any opening through which flue

gases could enter a building. The bottom of the vent terminal and the air intake must be located at least 12-inches (300mm)

above grade.

DO NOT cover the furnace.

Make sure that the correct gas supply is available.

The furnace requires a 120 V 60 Hz electrical supply.

The appliance, when installed, must be electrically grounded in

accordance with local codes, or in the absence of local codes with

the National Electrical Code ANSI/NFPA 70 (latest edition) or in

Canada with CAN/CSA-C22.2 No. 3.

Installations in the State of Massachusetts

All installations in the State of Massachusetts must use the following requirements when installing, maintaining or operating

direct-vent propane or natural gas-fired space heaters. For direct-vent appliances, mechanical-vent heating appliances or

domestic hot water equipment, where the bottom of the vent terminal and the air intake is installed below four feet above grade

the following requirements must be satisfied:

1.

If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and alarm

shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA 720 (2005

Edition).

2.

A carbon monoxide detector shall be located in the room that houses the appliance or equipment and shall:

a. Be powered by the same electrical circuit as the appliance or equipment such that only one service switch services

both the appliance and the carbon monoxide detector;

b. Have battery back-up power;

c. Meet ANSI/UL 2034 Standards and comply with NFPA 720 (2005 Edition); and

d. Have been approved and listed by a Nationally Recognized Testing Laboratory as recognized under 527 CMR.

A carbon monoxide detector shall:

a. Be located in the room that houses the appliance or equipment;

WARNING: For the installation of this furnace, the

following items must be used as a vent air intake

system:

External Vent Cap

(Part Number:

WFR–TRM000)

Flanged Air Inlet Tube

(Part Number:

WFR–TBO002)

Flue Outlet Tube

(Part Number:

WFR–795)

O-Ring

(Part Number:

WFN–RNG003)

(All the above items are supplied with the furnace)

WARNING: The nearest point of the vent cap should

be a minimum horizontal distance of six (6) feet

(1,830 mm) from any pressure regulator. In case of

regulator malfunction, the six (6) feet (1,830 mm)

distance will reduce the chance of gas entering the

vent cap.