High Altitude Adjustment

Based on the altitude of the installation site, reduce the manifold pressure specified in the “Technical Data” chart and as shown

in the table below:

Altitude

Manifold Pressure

Reduction Rate

0-2,000 ft

0%

2,000-3,000 ft

8%

3,000-4,000 ft

16%

4,000-5,000 ft

24%

5,000-5500 ft

32%

First Firing the Furnace

Start the furnace following the instructions given in the “Operating Instructions”. The first lighting may be difficult because of the

air trapped in the gas lines. During initial firing of the furnace, residual manufacturing grease will bake out and smoke will occur

which is not a health danger. To prevent nuisance and operation of fire alarms, ventilate the room for the first two hours of

operation.

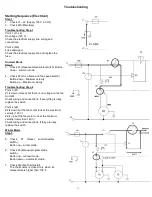

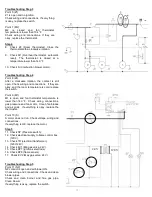

Checking the Gas Inlet Pressure

The gas inlet pressure can be measured by connecting a test gauge to the connection provided on the gas valve. (Figure 8 - A)

Once installation is complete, the gas inlet pressure must be checked. The minimum gas inlet pressure must be as shown in

“Technical Data”. After checking the gas inlet pressure, disconnect the test gauge and firmly tighten the screw of the gauge

connection, then check for gas leaks. Correct any gas leaks before operating the furnace.

Checking the Gas Manifold Pressure

The gas manifold pressure can be measured by connecting a test gauge to the connection provided on the gas valve. (Figure 8 -

B). The furnace comes set from the factory at the correct manifold gas pressure. After the installation is completed, the gas

manifold pressure must be checked both in Hi and Lo input. Turn the control knob to switch the unit from Hi to Lo input. The

position of the knob in which this occurs depends on the actual room temperature. The gas manifold pressure must be as shown

in “Technical Data”. Differences of plus or minus 0.1 in. w.c. are acceptable. If the Hi or Lo gas manifold pressures are different

from the values given in the “Technical Data” or are more than 0.1 in. w.c., shut off the furnace and contact a qualified service

technician for correction.

For instructions about adjustment of the manifold Hi and Lo pressures, see the "Servicing” section. After checking the gas

manifold pressure, disconnect the test gauge and firmly tighten the screw of the gauge connection, then check for gas leaks

from it. Correct any gas leaks before operating the furnace.

A

B

C

D

F

E

A. Test gauge connection for gas inlet

pressure

B. Test gauge connection for gas manifold

pressure

C. Nut for Hi pressure adjustment (pressure

regulator)

D. Screw for Lo pressure adjustment (Hi-Lo

operator)

E. Electric clamp connection

F. Gas supply inlet

Figure 8

11