WIKA operating instructions, model CTH7000

EN

12

08/2020 EN/BG

4. Design and function

4. Design and function

4.1 Principles of measurement

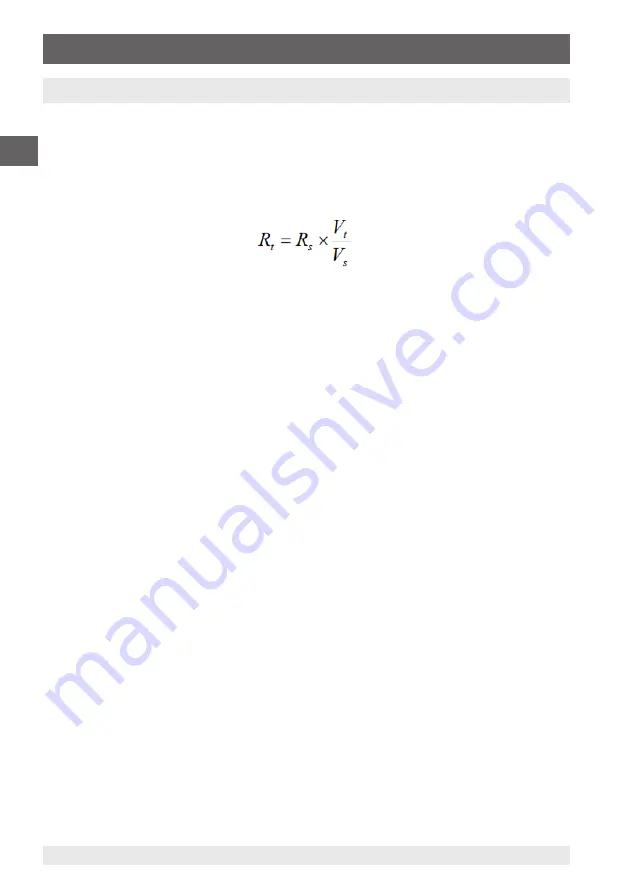

The CTH7000 measures the voltage (V

t

) developed across the unknown sensor

resistance (R

t

) and the voltage (V

s

) across a stable internal reference resistance (R

s

).

The voltages are proportional to the resistances so the thermometer resistance is derived

from.

This technique achieves immunity from slow moving time and temperature drifts in the

electronics, as it is not affected by voltage measurement gain variations or current source

fluctuations.

In the same way that AC resistance measurement eliminates thermal EMFs, switched

DC achieves a similar advantage. Switched DC works by reversing the current flow on

alternate measurement cycles and taking the average value, thereby cancelling any

thermal EMF offsets from the measurement.

For PRTs, the relationship between resistance and temperature varies slightly from one

PRT to another. Therefore, no matter how accurately the CTH7000 measures the PRT

resistance, if the relationship between resistance and temperature for a particular PRT

is not known, accurate temperature measurement is not possible. For thermistors, the

relationship depends totally on the thermistor type and specifications.

The CTH7000 uses PRT and thermistor calibration data to overcome this problem and

calculates the result from temperature conversion functions stored in either the sensors

‘SMART’ connector or the CTH7000’s internal non-volatile memory. This method enables

the CTH7000 to convert resistance to temperature, uniquely for each sensor used.

It is very important, therefore, that a sensor without a ‘SMART’ connector is used on a

properly configured input channel and that the probes’ coefficients are correctly entered

into the instrument.

System accuracy is a combination of the CTH7000 accuracy in measuring sensor

resistance and the calibration uncertainty placed on PRTs and thermistors by the

calibrating laboratory.