28

WWW.WETJETPOWER.COM

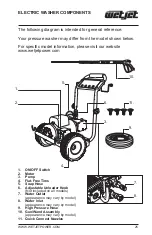

Caution:

Only a certified electrician can service the motor.

Contact an authorized dealer for service or additional

information.

User Maintenance Instructions

General Inspection:

Inspect the motor at regular intervals, approximately every 500

hours of operation or every 3 months, whichever occurs first. Keep the motor clean and

the ventilation openings clear. Check that the interior and exterior of the motor is free of

dirt, oil, grease, water, etc. Oily vapor, paper pulp, textile lint, etc. can accumulate and

block motor ventilation. If the motor is not properly ventilated, overheating can occur

and cause damage to the motor over time.

Lubrication & Bearings:

Lubrication from bearing grease will degrade over time. The

lubricating ability of grease depends primarily on the type of grease, the size of the

bearing, the speed at which the bearing operates, and the severity of the operation

conditions. Optimal results can be obtained if the following recommendations are

utilized in your maintenance routine.

Type of Grease:

A high-grade ball or roller bearing grease should be used. Recom-

mended grease for standard service conditions is Polyrex EM (Mobil).

Equivalent and compatible grease include:

Texaco Polystar, Rykon Premium #2, Pennzoil Pen 2 Lube and Chevron SRI-2.

- Maximum operating temperature for standard motors = 110°C.

- Shut-down temperature in case of a malfunction = 115°C.

Lubrication Intervals:

Recommended lubrication intervals are every 2200 hours. For

more information contact an authorized service center.

MAINTENANCE INSTRUCTIONS