The same procedure should be fol lowed for the

ground overcurrent circuit as was used for phase A

input.

Remove jum per from TP6 and TP7 on the

timer m odule.

Control Timer

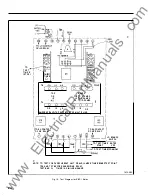

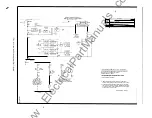

Refer to Fig. 4 and 5 or 6 when repl acing com

ponents.

If components in the control timer circuit have

been replaced or if it is desired to change the con

trol timer setting the same procedure should be

used as described under acceptance test ing.

Breaker Failure ( BF} Timer

If the scale appears to

be

o ff calibru tion due

to

slippage of the knob pointer on the shaft, this can

be corrected by rotating the shaft fully

CCW.

N ow

adjust the k n ob at the pin prick mark . This should

return the k n ob to its original position on the sha ft

and bring the scale markings back i nto calibration .

i f

components in the breaker failure timer cir

cuit have been replaced

it

may be necessary to

change the scale plate and recalibrate .

First

jumper test points TP6 and TP7. Using

a l cnv

bounce initiate switch adjust timer k nob until

a

25

ms time delay has been obtained . U se test

procedure described under acceptance testing for

measuring time delay. N ote the knob position for

25 ms delay . Also note the k nob position for 1 75

ms delay . Loosen the set screw and position the

k nob on the shaft so that the 25 and 1 75 ms

locations are equidistant about the knob locking

tab. Scribe lines at the 25 ms setting and for each

25 ms increment up to 1 75 ms.

Indicating Contactor Switch ( I CS)

Adjust the contact gap for approximately

. 047" by adjusting the stationary contacts. Both

contacts should make simultaneously.

Check to see that the contacts close at rated

tap va lue current. The indicating target should

drop at or just prior to the contacts closing. The

targer should drop freely.

I f the target does not drop or does n ot reset it

may be necessary to remove the cover and bend the

8

tab on the spring that supports

the

target.

T R O U B L E S H O OTI N G

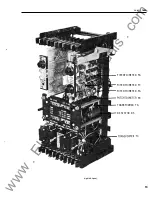

The components i n the S B F- 1 relay are

operated wel l within their rating and normally will

give l ong and trouble free service. H owever,

if

a

relay gives indication of trouble in service or dur

ing routine checks the fo ll owing informati on will

prove helpful. All measurements are approximate

a nd may vary as much as 20%. All voltages ar�;

p•Jsitive with reference to common negative ( reluy

term inal 8 ) except ac voltages .

Timer Module

l . Jumper

test

points TP6 and

TP7.

a . Apply rated relay voltage. Voltage

at

l ower

test j ack = 23 . 5 V

b . Rem ove jumper. Apply rated voltage .

Voltage at l ower test jack = 2 3 . 5

c::c.

1

Jumper test poi nts

TP6 and

TD7

:1 .

Apply rated relay voltage. Voltage

at

u oper

test jack = !es'i than 2 . 5

Ydc:.

h.

Rem ove jumper. A pply r:J�ed vollage .

Voltage at upper test jack = less t h a n

2 . 5

Vdc .

3 .

jumper test points TP6

and "':P7.

a. Apply rated voltage. Voltage at

term inal 6

of l e i = l 8 . 3 V .

b. Rem ove jumper. Apply rated voltage.

Voltage at terminal 6 o f

I

C I should be ap

proxim ately 0. 1 Vdc less than voltage

measured in section a.

4. Jumper test points TP6 and TP7.

a. Apply rated relay voltage. Voltage at ter

minal

7

of I C J = 20.8V with timer knob fully

CW .

b. Voltage at terminal 7 o f I C I = 23 . 8 V with

timer knob fully CCW.

5. Jum per test points TP6 and TP7.

a . Apply rated relay voltage. Voltage at ter

minal 2 o f I C l

=

1 6 . 5 V .

b . Remove jumper a n d apply voltage. Voltage

at terminal 2 of IC

I

should be approxi-

www

. ElectricalPartManuals

. com