30

feeder or liner.

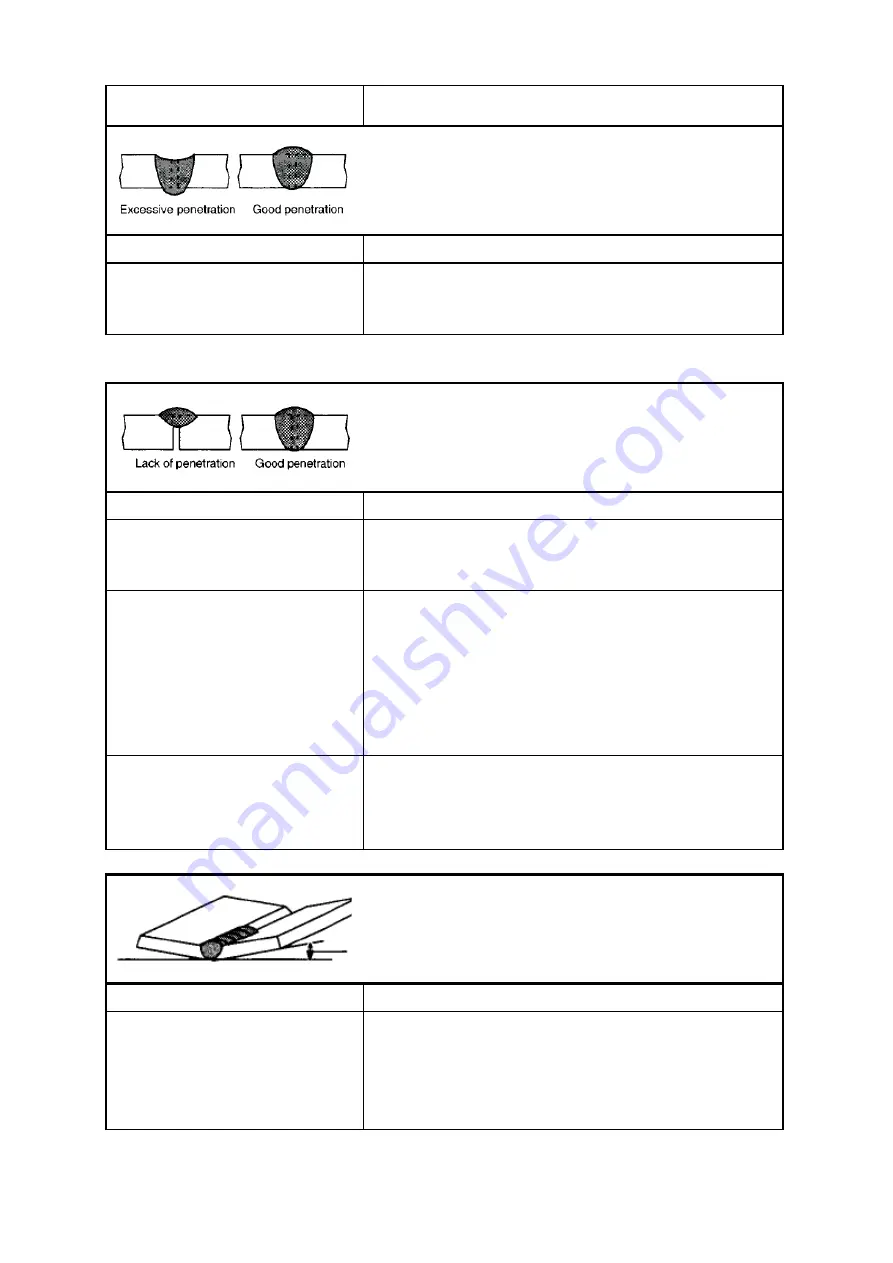

Excessive penetration

Weld metal melting through base metal and hanging

underneath it.

Possible causes

Corrective actions

Excessive heat input.

Select lower voltage range and reduce wire feed speed.

Increase travel speed.

Lack of penetration

Shallow fusion between weld metal and base metal.

Possible causes

Corrective actions

Improper joint preparation.

Material too thick. Joint preparation and design must provide

access to bottom of groove while maintaining correct welding

wire extension and arc characteristics.

Improper welding technique.

Maintain normal gun angle of 0 to 15 degrees to achieve

maximum penetration.

Keep arc on leading edge of weld puddle.

Be sure welding wire extends no more than ½ in beyond

nozzle.

Insufficient heat input.

Select higher wire feed speed and/or select higher voltage

range.

Reduce travel speed.

Distortion

Contraction of weld metal during welding that forces base

metal to move.

Possible causes

Corrective actions

Excessive heat input.

Select lower voltage range and reduce wire feed speed.

Increase travel speed.

Use restraint (clamp) to hold base metal in position.

Make tack welds along joint before starting welding operation.

Weld in small segments and allow cooling between welds.

Содержание TM250C

Страница 2: ...2...