53

TROUBLESHOOTING GUIDE, CONT’D.

PROBLEM

POSSIBLE CAUSE

BASE SYSTEM TEST PROCEDURE / REMEDY

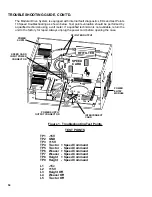

Chatter from

main drive unit

Clutch improperly

engaged

Knob should be seated firmly against drive unit. Turn drive clutch knob

fully clockwise while gently rocking the machine forward and backward

to fully engage the drive pinion. The rocking motion is necessary to help

ensure proper gear mesh (see page 6).

Wheel engagement

knob improperly

engaged

Wheel support bar should seat firmly against carriage rib. Turn the wheel

engagement knob (A) on the side of the carriage until the wheels are fully

moved towards the center of the carriage (engaged) (see page 6).

Carriage wheels out of

adjustment

Follow setup procedure for Wheel Adjustment and Alignment (page 7).

Worn or damaged rail

Visually inspect for damage or worn part. Replace if necessary.

Worn or damaged

pinion gear

Visually inspect for damage or worn part. Replace if necessary. See

Master Drive Unit / Technical Data (page 8).

Clutch assembly

improperly adjusted

Note: This is factory set. Examine all other possibilities first. For proper

pinion adjustment, allow 1/16th back lash in drive carriage movement on

rail. To increase or decrease pinion engagement, increase or decrease the

overall length of the clutch adjustment mechanism by adjusting items #32

and #37 on the MPD-1000 Master Drive Unit Exploded View / Parts List

(page 9).