49

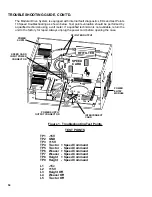

TROUBLESHOOTING GUIDE, CONT’D.

PROBLEM

POSSIBLE CAUSE TEST BASE SYSTEM TEST PROCEDURE / REMEDY

Bad power supply.

1G

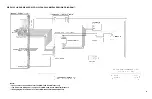

Turn on the main power. The green LEDs L1 and L2 (see Figure 1)

will light if the power supply is OK.

If the LEDs are off, unplug the power supply output connector

(see Figure 1). The connector wiring is: White & RED is +15 V DC

(+/-2V). White & Black is DC ground. White & Orange is -15V DC

(+/-2V). Measure the voltages at the connector.

a) A bad voltage indicates a defective supply. Replace the supply.

b) Correct voltages indicate the power supply is OK, however,

there is a short in the equipment. Plug in the power supply

output connector. Perform test 1H.

Short circuit.

1H

The Green LEDs L1 and L2 will light when the short is removed.

Unplug the following and monitor the LEDs to see if the short is

removed: 1) The control module 2) The speed card input power

connector (see Figure 1). 3) All connectors attached to the

interconnect card (see Figure 1), except the connector from the

supply.

If L1 and/or L2 never turned on, the interconnect card is bad.

Replace the board.

No tractor

speed

control and

display is lit.

Operator Error

(Stitch Control

Module).

2A

Set the MODE switch to CONTINUOUS WELD and the CARRIAGE

TRAVEL switch to STOP. Turn the SPEED CONTROL clockwise.

Proceed to step 2C if the display does not increase. If the display

does increase, then turn the CARRIAGE TRAVEL switch to

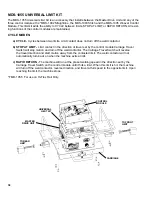

FORWARD. Open the master drive case (Figure 3) and proceed to

step 2D if the tractor does not move forward.

Operator Error

(Weaver Control

Module).

2B

Set the MODE switch to RUN , the CARRIAGE TRAVEL switch to

STOP and the START/STOP switch to START. Turn the SPEED

CONTROL clockwise. Proceed to step 2C if the display does not

increase. If the display does increase, then turn the CARRIAGE

TRAVEL switch to FORWARD. Open the master drive case (Figure

3) and proceed to step 2D. If the tractor does not move forward.

Bad DC power.

2C

Open the master drive case (Figure 3). Unplug the power supply

output connector (see Figure 1). The connector wiring is: White

& Red is +15 V DC (+/-2 V). White & Black is ground. White &

Orange is -15 V DC (+/-2 V). Measure the voltages at the connector.

A missing or bad voltage indicates a bad supply. Replace the supply.

Faulty motor wiring.

2D

Check the wires from the speed card to the motor for faults.

Rewire if needed.