21

4

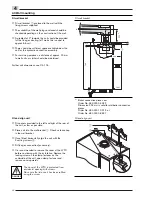

4.4 Mains water connection

Hydraulic connection

1 Heating flow Ø 18 mm

2 Flow water heater or DHW Ø 15 mm

3 Gas Ø 18 mm

4 Return water heater or cold water Ø 15 mm

5 Heating return Ø 18 mm

6 Condensate outlet Ø 25 mm

Application in sealed heating systems

☞

On version -W: Connect flow and return pipes of

water heater.

☞

On version -C: Connect cold and hot water pipes.

☞

Connect flow and return (pipes should be rinsed

thoroughly before connecting).

☞

Install boiler, inlet and outlet valves

(available as an accessory).

☞

Install safety valve (available as accessories).

☞

Fit sludge trap in return pipe (if required).

☞

Fit expansion tank (WTC 32-A)

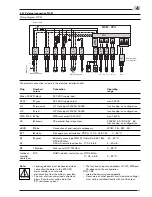

335

50

120

ca. 8

0

0

77,5

260

35

50

9

9,2

240

1

2

3

4

5

6

6

1

2

3

4

5

40

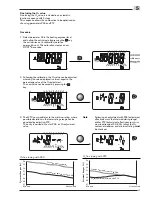

4.5 Filling with water

When filling the heating system, the requirements for the

heating system water (see also Ch. 3.4) should be

observed.

Unsuitable water results in scaling and

corrosion formation and can cause damage

to the condensing boiler.

Centre position three way valve

☞

Check pre-pressure of the diaphragm expansion

vessel.

☞

Prior to first commissioning, the heating system

should be flushed with at least twice the amount of

the system content to remove contaminants. Swarf,

rust, scale, sludge etc. can influence the operational

safety.

☞

Set three way valve of condensing boiler to it centre

position (only on version -W and -C).

☞

Open all thermostatic valves in the system.

☞

Loosen cap of quick action vent valve.

☞

Open service cocks for heating flow and return.

☞

Slowly fill heating system from tap connected to the

heating return (minimum system pressure >1.0 bar).

Observe all relevant regulations.

☞

Vent all radiators.

☞

Once the system has been vented, check system

supply pressure, if necessary repeat fill procedure.

☞

Seal joints and screwed unions should be checked to

ensure they are tight.

Note:

The unit and any separately fitted pumps

must be switched off during filling.

ATTENTION

Содержание thermo condens WTC 15-A

Страница 92: ...92 Notes A ...

Страница 93: ...93 A ...