16

3

3.4 Prerequisites

Included in delivery

The ready-to-use unit is delivered in a cardboard box.

The following parts are enclosed loose:

•

End user documents

•

Wall bracket

•

Screw set with wall plugs

•

Installation template

•

Spacer

Application instructions

When transporting and storing the unit, the following

should be avoided:

•

mechanical impact, such as: distortion,

warping, scratching

•

contamination of any kind, e.g.: water, oils, greases,

solvents, dust, debris, aggressive steam, etc.

•

electrical impact, e.g.: through electrostatic discharge

or unnaturally large electric fields, see DIN EN 100

015 Part 1 and "Instruction for handling

electrostatically sensitive components" (techn.

information 821005 from Valvo)

•

climatic exposure, such as: temperatures outside of

the range -10°C...+60°C, condensation caused by

dew, rel. humidity above 75% as annual average.

Requirements relating to the installation location

The installation location, which should be frost free and

protected from humidity, must comply with local

regulation (combustion by-law, fire regulations).

Observe special regulations:

•

DVGW-TRGI (Germany)

•

SVGW-Guidelines (Switzerland)

Requirements relating to combustion air

The combustion air must be free from aggressive

compounds (Halogene, Chloride, Fluoride, etc.) and from

contaminants (dust, building material, steam, etc.). The

unit should not be operated until all building work in the

installation location has been completed.

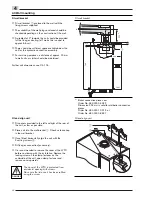

Flue gas connection to chimneys

Due to the water vapour content in flue gases with low

temperature and the additional condensation created in

the chimney, condensing boilers can only be connected to

moisture resistant house chimneys. The flue gas ducts

must comply with local authority regulations and country

specific requirements:

•

(DE)

DVGW (TRGI)

•

(AT) ÖVGW

•

(CH)

SVGW, VKF Guidelines, Number 3.4.8

(Issue 1993)

Building regulation approved flue gas duct

The flue gas duct should have the same diameter as the

boiler flue gas socket.

•

Consultation with the appropriate district master

chimney sweep

•

Flue gas duct soundness test must be carried out

Air inlets must be

kept clear!

Unimpeded combustion air

Important - Warranty for boiler replacement!

Supply air ducts, which have previously been used as a

chimney for solid fuel or oil firing plants, must only be used

as supply air duct once they have been thoroughly

cleaned. Thoroughly clean means that dust, sulphur, soot,

dirt and any diffused gases have been removed from the

duct material (e.g. paint, render, insulation). If unsure, the

internal sides of the duct should be sealed or concentric

flue gas pipes (accessory) should be used.

If the WTC is integrated into an existing heating system, it

must be ensured that rust, dirt and sludge have been

removed. Non oxygen diffusion resistant plastic pipes must

only be connected via a separate heat exchanger,

otherwise deposits can cause damage and lead to

operational influences (localised overheating, noise or

similar). On version -C it should be noted that galvanised

steel pipes must not be connected to the DHW

connections.

☞

If necessary fit sludge strainer in the return

Flue gas duct

Содержание thermo condens WTC 15-A

Страница 92: ...92 Notes A ...

Страница 93: ...93 A ...