16

Anchoring to Weak Pinchwelds

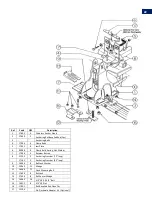

Pinchwelds vary from car to car. Some have good strength for heavy sideway pulls but

not for down pulls. On other cars, the pinchwelds might be strong at the front but

weak at the rear. Careful examination can usually determine what the limitations of the

car’s pinchwelds are. Look for at least three layers of metal coming together on the

edge of the pinchweld flange. The figure to the left shows a cutaway of a reinforced

pinchweld section. Look for spot welds along the outside of the sill to indicate possible

inner layers of metal.

Side Sill Inner

Side Sill Outer

Floor Panel

Reinforcement

Commonly

Reinforced

Areas

After examining the metal thickness and strength of the pinchweld, you can locate the

pinchweld clamps accordingly. The 1988 and 1989 Toyota vans, for example, cannot be

secured by the pinchweld flanges.

Anchoring with Obstructions on the Pinchweld

The Wedge Clamp pinchweld clamp has been specifically designed to fit around

obstructions and at the same time provide maximum holding strength. It may be

necessary to remove fuel lines, etc. out of the way before clamping the pinchweld

flange. In some cases it may be necessary to remove fender bolts and even pull the

bottom of the fender out from the car in order to fit the pinchweld clamp in the

strongest location. In very difficult obstruction situations, it is possible to remove one

of the jaws on the clamp so that the clamp is anchoring the vehicle with only one jaw

(see “Anchoring Cars with Very Short Pinchwelds” below).

NOTE: Care should be taken not to clamp over drain contours on some pinchwelds

thereby pinching them shut.

Anchoring with Very Short Pinchwelds

On some vehicle models, the pinchwelds are very short (such as on the Chevrolet

Sprint and Honda Accord). It is necessary to remove one of the jaws on each clamp so

that only one jaw is holding the pinchweld. This method has been tested under various

conditions and has been found to hold satisfactorily.