WDT Operating instructions GRANUDOS 10 (V61-08/05) page 4 of 20

____________________________________________________________________________

1.2

Dosing Assembly

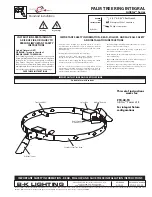

The dosing assembly, placed into the main housing consists of the dosing hopper (5a) and the dosing

unit with dosing motor (6a) pushed into and screwed to the motor holder (6b) the dosing

screw (6c) and the dosing nozzle which is heated eliminating condensation of the warm pool water

vapour. The dosing unit is screwed into the dosing hopper. The required dosing rate is adjusted at the

control board by means of a dosing cycle and dosing time – see para 1.5.

5a

dosing hopper

5b

hopper cover

6a

dosing motor

6b

motor holder

6c

dosing screw

6d

heated dosing nozzle

6e

knocker

The knocker (6e) gives a stroke to the dosing hopper wall

and thus prevents clogging of the chemical.

The complete dosing assembly can be taken out of the

frame for service.

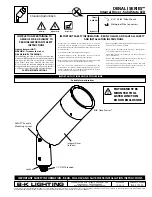

With the shown fitting systems chemical containers of 10 kg can be fitted directly to the hopper so that

the chemical must not be moved from the container to the hopper.

Fitting system to join a

Fitting system to join a

10 kg container with round edge

10 kg HTH container