7 of 14

WX-501-0537 • 01.22

Note.

If a vehicle exceeds the anticipated maximum speed and length, then the detection event may not

be generated until the vehicle’s ETA is less than the desired value. In this case, the output will activate upon

reception (without any additional delay).

In order to trigger an ETA to a sign:

1. Select the Automatic (English) configuration options.

2. Specify the corresponding setback distance in feet. In this case, the setback distance is from the location of

the SmartSensor HD unit to the location of the warning sign.

3. Specify the ETA in milliseconds.

4. Specify the duration in milliseconds.

Note.

If your SmartSensor HD unit is configured in Metric units, select the

Automatic (Metric)

configuration option.

In this case, the setback distance is specified in decimeters instead of feet.

Since vehicles travel at different speeds, the amount of time from when the front edge of the vehicle enters the

beam until it reaches the warning sign is variable. In addition, the amount of time the vehicle is in the beam is also

variable (based upon vehicle speed and length).

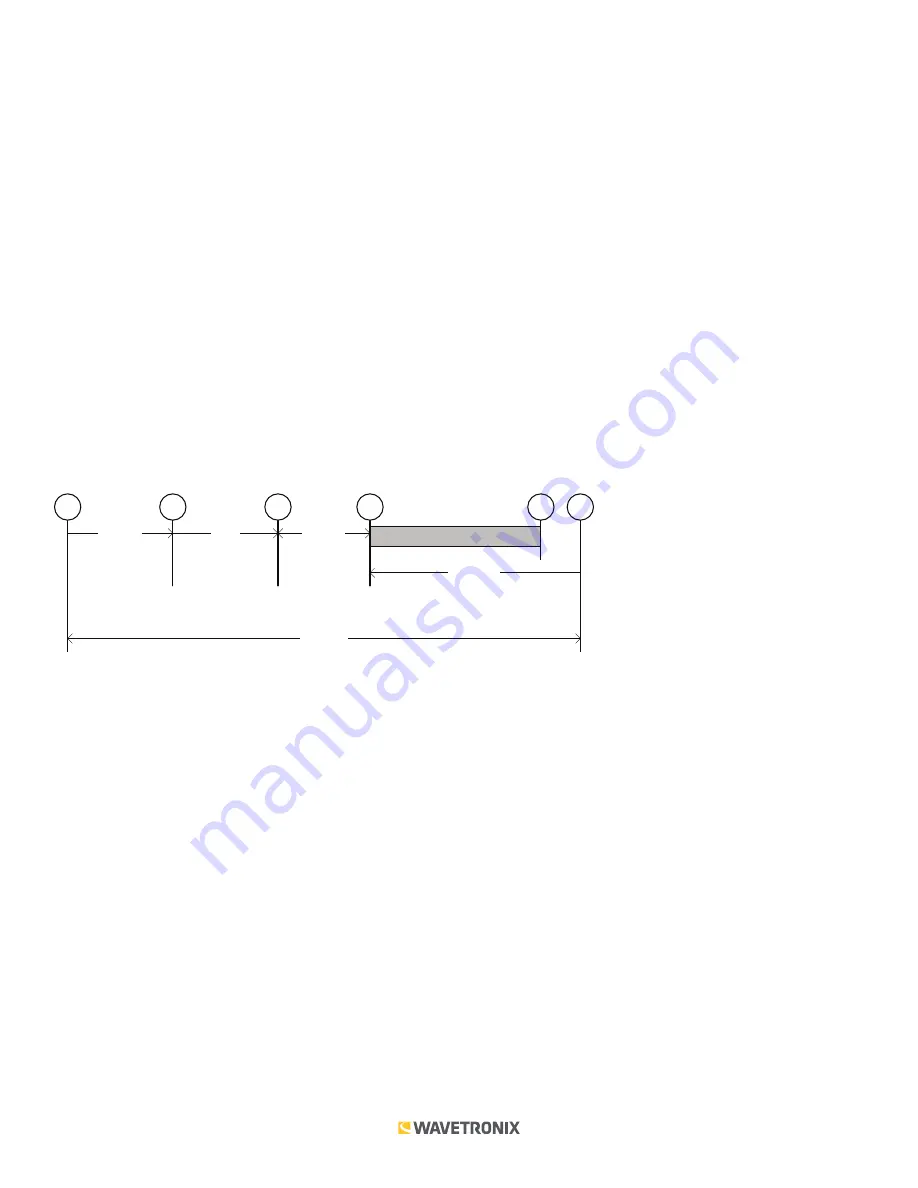

The following diagram illustrates the basic timing of this option as a series of six steps. Some portions of the timing

are variable and others are fixed.

variable

L_ft / V_fps

fixed

1 s

variable

ETA (ms)

Duration (fixed)

1

2

3

4

6

5

variable

Time to Sign = SetbackDistance_ft / V_fps

1. Front edge of vehicle enters beam.

2. Back edge of vehicle leaves beam. The time from point 1 to point 2 is variable and is based on the length and

speed of the vehicle.

3. Detection event is generated one second after the vehicle leaves the beam. This one-second delay is fixed.

4. Output is activated.

5. Output is deactivated at the end of the duration.

6. Front-edge of vehicle reaches the sign (assuming constant speed).

Note.

You can have a maximum of five vehicles concurrently being monitored from steps 3 to step 4. If you have

extremely high traffic flow conditions where multiple over-speed/over-length vehicles are possible, consider

dedicating a single output to each lane to prevent dropping detections.

Note.

The 35-byte serial communication delay from the sensor to the Click 512 is 3 ms at 115.2 kbps. The 9-byte serial

communication delay from the Click 512 to the Click 104/112/114 is 2 ms. This is a total of 0.005 seconds of additional

delay (not depicted in preceding graph). At 9600 bps, this increases to up to 0.038 seconds of additional delay.

The second method, the point trigger method, also provides a certain level of uniformity, in that the warning sign

is activated when vehicles reach a certain point. However, the warning sign will deactivate at different points since

the duration is a predetermined fixed period of time. This method can require a setback distance of 300 (or more)