3 of 14

WX-501-0537 • 01.22

The Click 500 series module has two DIP switches on the left side of the module. The DIP switches are used to

program or reprogram the unit; however, for all Click 512 applications, these DIP switches are unused.

Note.

The sixth switch of DIP switch 1 controls the mode of the device. Make sure that this switch is in the OFF

position. If it gets turned on, the device will enter Program mode and all of the faceplate LEDs will turn off when a

serial connection is made. To exit Program mode, power will need to be cycled on the device.

Configuration Features

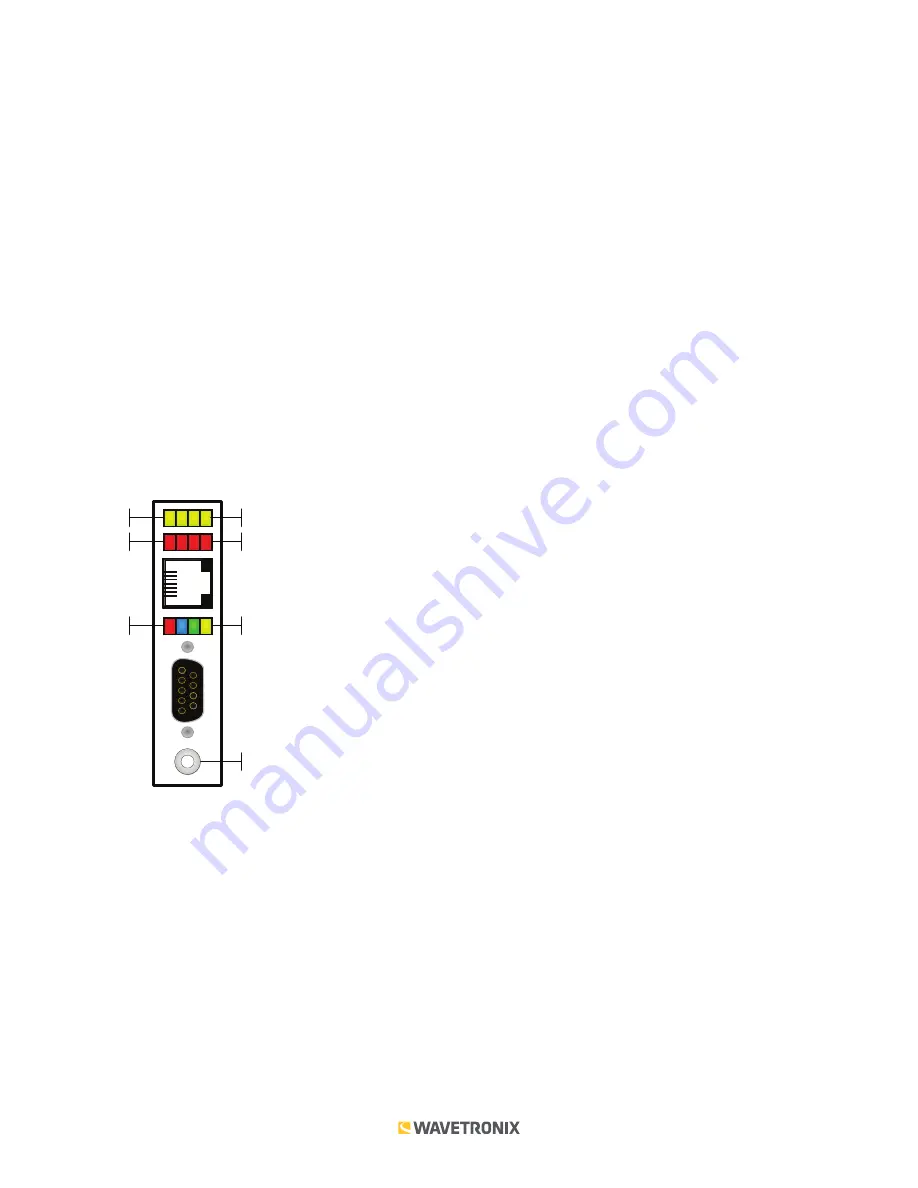

There are three banks of LEDs located on the front of the Click 512.

The yellow and red banks of LEDs display submenu selections and application information. See the Operating

Modes section of this document for more information.

The system LEDs (multicolored bank in the middle of the module) have dual functions: they are activity indicators,

reporting system status information, and they are also used in selecting operation modes from the main menu.

The blue LED does not have an activity-indicating function. The other three LEDs indicate system status as follows:

■

PWR (red) lights up when the device has power.

■

TD (green) lights up when the device is transmitting data.

■

RD (yellow) lights up when the device is receiving data.

Sub Menu 1

Sub Menu 2

Main Menu

Push-button

Yellow LEDs

Red LEDs

Multicolored LEDs

If the Click 512 receives data via one port it will forward (transmit) the data to the other ports. However, only the RD

(yellow) light will flicker in this case. The TD (green) light is reserved for data originating from the Click 512.

Located on the front of the module below the DB-9 connector is a push-button labeled

Mode Switch

. The push-button

allows you to make selections from the menu. See the Operating Modes section of this document for more information.

Installation

Make sure that the Click 512 is installed on a T-bus with active power and RS-485 communication.

If you are going to use your Click 512 in conjunction with a computer serial port and terminal program, the RS-232

DB-9 port on the front of the device can be used to make a connection between the Click 512 and the computer.

Obtain the desired serial terminal program and follow the distributor’s instructions to install.