Benchmark 750-3000 Installation & Startup Manual

SECTION 5

– SAFETY DEVICE TESTING

OMM-115_D

•

GF-200

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 85 of

126

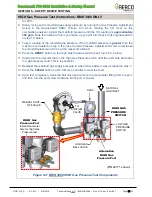

HIGH Gas Pressure Test Instructions: BMK 3000 ONLY

to 100%.

8. Slowly increase the manifold gas supply pressure by turning the Gas Pressure Adjustment

Screw in the Downstream SSOV (Figure 4-3) while reading the CO level on the

combustion analyzer. Adjust the manifold pressure until the CO reading is

approximately

300 ppm

. Note the number of turns you make, as you will turn it back to its original position

in step 10, below.

9. Take a reading of the manifold gas pressure. If the manifold pressure is

greater

than the

maximum calculated in step 3, then use the Gas Pressure Adjustment Screw to decrease

the manifold pressure until it is at the maximum allowed.

10. Press the

RESET

button on the High Gas Pressure switch (see Figure 5-4, below).

11. Slowly turn the indicator dial on the High Gas Pressure switch until the unit shuts down due

to a gas pressure fault. This is the setpoint.

12. Readjust the manifold gas supply pressure to what it was before it was increased in step 7.

13. Press the

CLEAR

button on the C-More Controller to clear the fault.

14. Upon test completion, close the ball valve and remove the manometer fitting from the port,

and then turn the port screw clockwise till the port is closed.

Figure 5-4:

BMK 3000

HIGH Gas Pressure Test Components

TO

AIR/FUEL

VALVE

MANUAL SHUT-

OFF VALVE

HIGH Gas

Pressure Port

Install manometer

here for High Gas

Pressure test

LOW GAS

PRESSURE

SWITCH

HIGH GAS

PRESSURE

SWITCH

Alternative

HIGH Gas

Pressure Port

HIGH GAS

BALL VALVE

SSOV

NATURAL

GAS INLET

(P/N 22171 shown)