8

- System Start Up Procedure -

IMPORTANT NOTE:

Tank should be filled with water and media must have been soaking for at least 1 hour

before initial pressurization

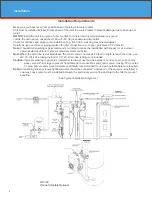

1. After all plumbing and drain line connections have been made, turn main water supply back on and

check for leaks.

2. Ensure that the bypass valve is in the BYPASS position, and then cycle the control valve to RAPID RINSE.

Once the rapid rinse step is reached, slowly open the bypass valve to the service position, allowing water

to flow down through mineral tank and out the drain line. Let it continue to run for the entire rapid rinse

step (5 minutes). There may be colored water or media fines during this initial flow.

3. Once the rapid rinse ends, leave the system in service, and open a cold, treated water tap. Let water run

for several minutes to allow air and any media fines to be released from the lines. Once air is evacuated

and water runs clear, close the tap.

NOTE:

Any time media (other than very fine mineral on initial startup) is apparent in the service lines, it

usually indicates one of the following problems:

A. The unit is plumbed in backward allowing the media to be carried in the service line.

B. The distributor tube inside the tank is not seated inside the valve or is damaged.

4. No further regeneration should be necessary at this time. If left at the default settings, the filter will

automatically initiate an air replenish cycle each night and will backwash every six days. If desired, these

settings can be changed in the main menu, or from the “advanced settings” screen in the Legacy View

app.

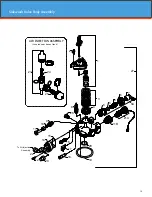

- Electrical Connection -

1.

Connect the power cord and plug power supply into a 115 volt / 60 Hz receptacle.

Note :

Do not plug into an outlet controlled by a wall switch or pull chain that could inadvertently be turned

off

Electronic Connections

P = Power Supply - Input Jack

OUTPUT JACKS

B = Powered in Air Replenish Step Only

(Cycle #4 - typically used for Oxy-03 Ozone)

S = Powered for Entire Backwash Cycle

(Not typically used)

P B S

Installation

Содержание SIDEWINDR SW10

Страница 1: ...Installation Operation Manual...

Страница 30: ...30...

Страница 31: ...31 710 Orange Street Ashland OH 44805 PH 419 289 1500 FAX 419 289 1515 www watersoftinc com 0423TV...