20

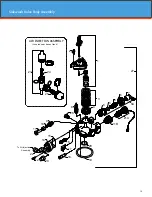

Sidewindr Valve Body Assembly

REF

DESCRIPTION

PART NO.

QTY

1

Piston Assembly Final Rinse

20009X231

1

2

10-24 X 3/4” Screw SST

20001X001

5

3

Seal and Spacer Kit

20561X253

1

4

End Spacer

20001X234

1

5

Flow Control Button 5.0 GPM

20251X272

1

Flow Control Button 7.0 GPM

20251X273

1

6A

DLFC Housing

20017X251

1

7

Drain Line Hose Barb 90 ° Elbow

20017X266

1

8

Brine Valve

20009X225

1

9

BLFC Assy. SST

20009X228

1

10

BLFC Ferrule 3/8”

20251X305

1

11

Plug 3/8”

20009X005

1

12

10-24 X 3/4” Screw SST

20001X226

2

13

3/8” Push Lock Plug

20009X010

1

14

Injector Cap

20009X001

1

15

Injector Seal

20001X224

1

16

Injector Assy. #1 White

20017X219

1

17

Injector Screen

20001X222

1

18

Injector Plug & O-Ring Assy

20001X217

1

19

Tank / Valve O-Ring

20015X043

1

20

Dist. O-Ring

20561X204

1

21a Meter Assembly

20017X203

1

21b Meter Plug w/ O-Ring

20017X201

1

22

3/8” Push Lock 90 ° Elbow

GA-Q0620626BV

1

23

Air Injector Check Assy

20017X010

1

24

Injector, White

20017X219

1

25

Check Valve

20017X009

1

26

1/4” NPT Cap

20018X035

1

Содержание SIDEWINDR SW10

Страница 1: ...Installation Operation Manual...

Страница 30: ...30...

Страница 31: ...31 710 Orange Street Ashland OH 44805 PH 419 289 1500 FAX 419 289 1515 www watersoftinc com 0423TV...