Warning

Keep away from the front of the spray gun - imminent risk of injury.

Warning

Make sure that nobody is present in the spraying zone when the gun is started -

imminent Risk of Injury.

1. Start the gun to produce a spray pattern sample (see

5.2. Starting/Stopping

Requirements

).

2. Inspect the sample and readjust the settings of the gun as may be required

(see

5.4 Spray Pattern Adjustments

).

5.4

Spray Pattern Adjustments

The spray pattern of the of the series PILOT WA 7XX models can be adjusted as

follows:

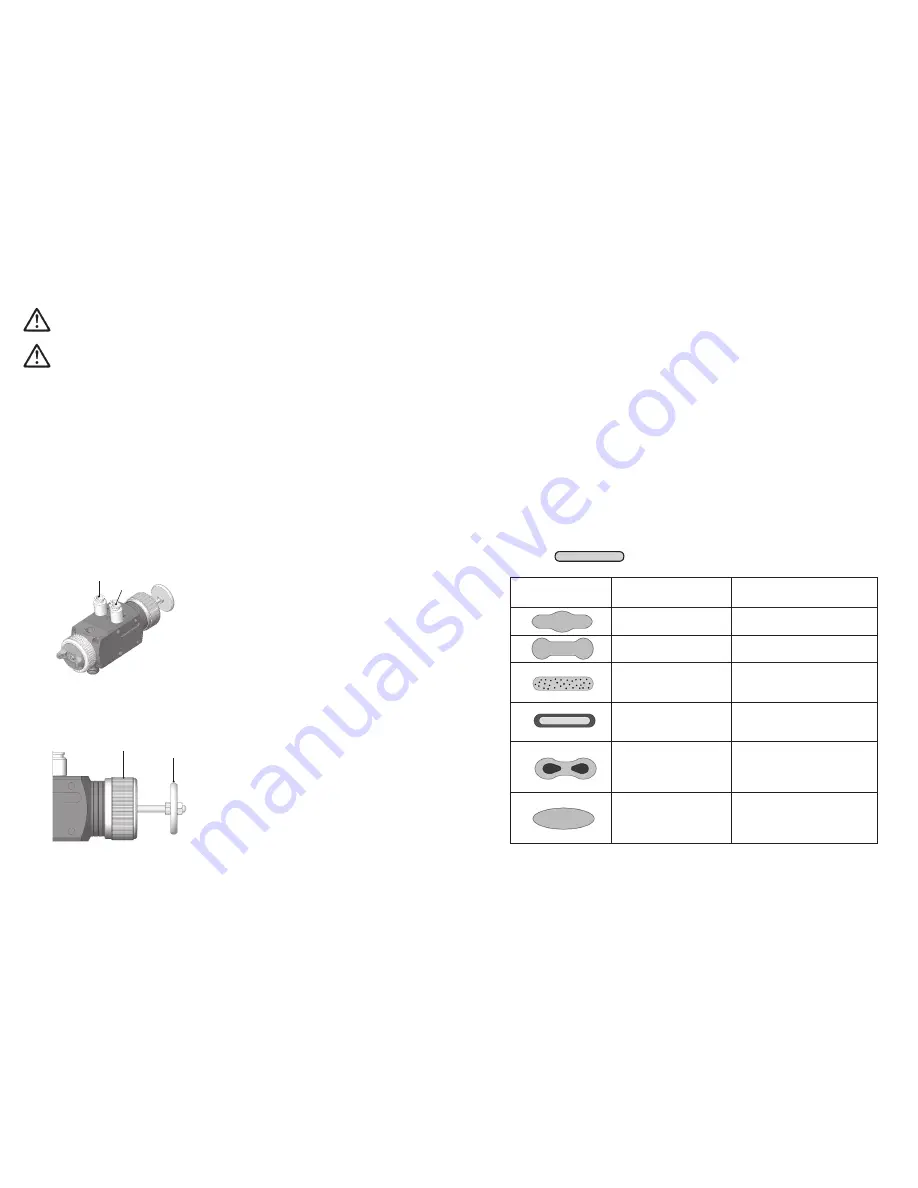

Adjusting the jet pattern

Adjustment of the material flow rate

R

B

The spray pattern is adjusted by a ressure

regulator in the plant (see operating

instructions of plant systems manufacturer).

The connection

B

is for the wide jet,

the connection

R

is for the round jet.

Turn cap (1) from the standard position.

• to the inside in order to decrease the material

flow rate.

• to the outside in order to increase the material

flow rate.

The material flow through the nozzle can be

performed without using atomizing air, when the

drawbar (2).

8

2

1

Adjustment of the Material Pressure

This adjustment can only be made at the pump or the material pressure tank.

Please comply with the operating instructions and safety warnings issued by the

manufacturers concerned.

Adjustment of the Atomizing Air Pressure

The atomizing air pressure is adjusted at the air pressure reducing valve of the

compressor system. Please comply with the operating instructions and safety war-

nings issued by the manufacturer.

If you wish to change the spraying pattern beyond the adjustments outlined so far,

you must retool the spray gun (See

5.5 Retooling of Spray Gun

).

WALTHER offers a great variety of air cap/-material nozzle/needle combinations for

this purpose.

Correcting of Spray Pattern Imperfections

The following table shows what to do to correct a spray pattern.

desired spray result

Spray pattern

test

Fault

Necessary adjustment

Swollen centre

• Spray jet should be flatter

Swollen ends

• Spray jet should be rounder

Coarse pearl effect

• Increase atomising air

pressure

Unduly thin paint layer in

centre

• Decrease atomising air

pressure

Split centre

• Increase nozzle diameter

• Reduce atomising air

pressure

• Increase material pressure

Split centre

• Decrease material pressure

• Increase atomising air

pressure

9