39

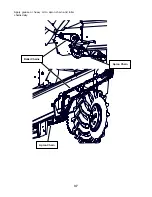

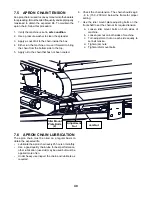

7�4�2 DRIVE BELT TENSION / REPLACEMENT (IF EQUIPPED)

The machine is designed with a sheave on the PTO shaft, which is used to drive the line shaft sheave through a

pair of drive belts.

When the belt is in disrepair or loose, the ability to efficiently drive the line shaft may be affected. It is important to

periodically check the condition as well as the tension of the belt. Frayed, cracked or worn drive belts should be

replaced. Drive belt should deflect no more than 3/4 - 1.0 in. (19 - 25 mm).

For accurate measurement use a drive belt tension gauge. Contact your dealer for more information on belt tension.

To replace the belt follow this procedure.

1. Verify the machine is set in

safe condition�

2. Remove the bolts that secure the belt shield, and

remove the shield.

3. Loosen (do not remove) the 4 bearing mount plate

bolts that hold the PTO bearing/ shaft assembly to

the main frame.

4. Turn the belt tensioning nut counter clockwise, until

the drive belts are loose enough to remove, then

remove the belts.

5. Install new belts.

6. Turn the belt tensioning nut clockwise to tighten

the belt.

7. Check the tension by pushing on the belt with your

finger and measure its defection. Drive belt should

deflect no more than 3/4 - 1.0 in. (19 - 25 mm).

8. Check pulley alignment then tighten four PTO

bearing/ shaft assembly bolts. Replace the belt

shield, cover and reinstall the bolts.

9. Recheck tension after 10 hrs of use.

Bearing

Mount Plate

Bolts (4)

Belt Tension Nut:

1. To tighten turn

clockwise.

2. To loosen

turn counter

clockwise.

Drive Belts

WARNING

Machine is shown with guard

removed for illustrative purposes

only� Do not operate machine

with guard removed�