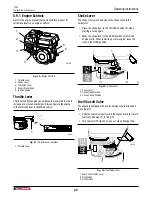

Inspection

•

Remove the air cleaner cover.

•

Remove the foam filter element from the paper filter

element.

•

Clean or replace dirty filter elements. Always replace

damaged filter elements.

NOTE:

Refer to the engine manual for further

information on servicing the air cleaner.

1

2

3

4

5

6

00455

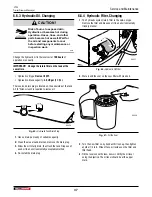

Fig. 29 –

Engine Air Cleaner

1. Wing Nut

2. Air Cleaner Cover

3. Wing Nut

4. Paper Filter Element

5. Foam Filter Element

6. Gasket

Hydraulic Oil Level Check

Check hydraulic oil level daily

with the engine stopped.

Pull out the dipstick to check the oil level.

The correct level is

when the oil is at the upper mark on the dipstick

. Add oil as

required.

IMPORTANT! Do not operate machine if oil level is low.

Damage to the pump and other components can occur.

IMPORTANT! Hydraulic oil quality should be inspected

every 50 hours. If the oil is dirty or smells burnt, it should be

replaced.

00536

3

2

1

Fig. 30 –

Hydraulic Oil Level Check

1. High Oil Level Indicator Mark

2. Low Oil Level Mark

3. Oil level Dipstick in Reservoir

Adding Oil to the Tank

The hydraulic system uses

Dexron® III ATF

.

3.

Clean the area around filler cap and remove it.

4.

Use a clean funnel to add oil. Check the level by inserting

the dipstick then removing it to examine.

5.

Install filler cap securely afterward. Wipe up any spilled oil.

Check levels after changing filters or servicing hydraulic

components.

CT24

Trailer Firewood Conveyor

Operating Instructions

29

Содержание CT24

Страница 1: ...OPERATOR S MANUAL Trailer Firewood Conveyor CT24 S N CT244 Up CT24 Part Number Z97163_En Rev Feb 2022...

Страница 46: ......

Страница 47: ......

Страница 48: ...www wallensteinequipment com...