3

HERO 23D / Hero 23 / SF 23 Pro

GB

CONTENTS

D

Contents

1

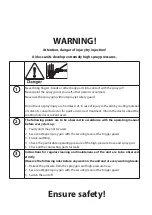

SAFETY REGULATIONS FOR AIRLESS SPRAYING 4

1.1

Flash point ___________________________________4

1.2

Explosion protection ___________________________4

1.3

Danger of explosion and fire from sources of

ignition during spraying work ___________________4

1.4

Danger of injury from the spray jet _______________4

1.5

Secure spray gun against unintended operation ____4

1.6

Recoil of spray gun ____________________________4

1.7

Breathing equipment as protection against

solvent vapors ________________________________4

1.8

Prevention of occupational illnesses ______________4

1.9

Max. operating pressure ________________________5

1.10 High-pressure hose ___________________________5

1.11 Electrostatic charging

(formation of sparks or flames) __________________5

1.12 Use of units on building sites and workshops _______5

1.13 Ventilation when spraying in rooms ______________5

1.14 Suction installations ___________________________5

1.15 Earthing of the object __________________________5

1.16 Cleaning the unit with solvents __________________5

1.17 Cleaning the unit _____________________________5

1.18 Work or repairs at the electrical equipment ________5

1.19 Work at electrical components ___________________5

1.20 Setup on an uneven surface _____________________6

2

TECHNICAL DATA ___________________________ 6

3

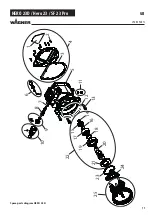

REPAIRS AT THE UNIT _______________________ 7

3.1

Inlet valve ___________________________________8

3.2

Outlet valve __________________________________9

3.3

Pressure control valve __________________________9

3.4

Replacing the power cable ____________________ 10

3.5 Troubleshooting ____________________________ 11

4

SPARE PARTS ______________________________ 12

4.1

Spare parts list Hero 23D _____________________ 12

4.2

Spare parts list high-pressure filter (accessory) ____ 18

4.3

Spare parts list hopper _______________________ 18

4.4

Spare parts list trolley ________________________ 19

4.5

Spare parts list suction system _________________ 19

4.6

Spare parts list suction system Japan ___________ 20

ELECTRICAL REPAIR INSTRUCTIONS

1

BASIC PRINCIPLES ________________________ 21

1.1

Electrically instructed person __________________ 21

1.2

Skilled electrician for defined tasks _____________ 21

1.3

Legal foundations ___________________________ 21

1.4

Which tests must be performed ________________ 21

1.5

Five safety rules _____________________________ 22

1.6

Categorisation of protection classes ____________ 23

1.7

Explanation of electric variables and components _ 24

1.8

Explanation of electrical terms _________________ 24

2

FUNCTIONAL TEST WORK INSTRUCTIONS ____ 26

2.1

Functional test of cord set ____________________ 26

2.2

Functional test of capacitor ___________________ 26

2.3

Functional test of switches/buttons _____________ 27

2.4

Functional test of earthing contact socket _______ 27

2.5

Functional test of the motor overcurrent

protection switch ___________________________ 27

2.6

Functional test of the threephase motor _________ 28

2.7

Functional test of AC motor ___________________ 28

3

REPAIR WORK INSTRUCTIONS _______________ 28

3.1

Replacing a cord set _________________________ 28

3.2

Replacing a 400 V cord set ____________________ 29

3.3

Replacing the capacitor ______________________ 29

3.4

Replacing switches/buttons ___________________ 29

3.5

Replacing the earthing contact socket __________ 30

3.6

Replacing the motor protecting switch __________ 30

3.7

Replacing the threephase motor _______________ 30

3.8

Replacing the AC motor ______________________ 31

4

MACHINE-SPECIFIC DOCUMENTS ____________ 32

4.1

Connection diagram Hero 23D /SF 23 Pro _______ 32

4.2

Connection diagram Hero 23 (Japan) ___________ 33

4.3

Connection diagram Hero 23 (Taiwan) __________ 34