9

HERO 23D / Hero 23 / SF 23 Pro

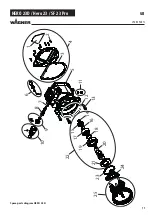

REPAIRS AT THE UNIT

3.3

PRESSURE CONTROL VALVE

1. Insert regulator (10) and tighten it.

2. Mount stop sleeve (4) and clamp (3).

3. Turn pressure regulation screw (6) to the left until the

spring snaps (pressure = 0).

4. Attach suction system or hopper.

Test medium: water

5. Mount a pressure gauge (0 – 400 bar), an original pressure

hose from Wagner and a high pressure airless gun.

3.2

OUTLET VALVE

1. Use a 22 mm wrench to screw the outlet valve from the

paint section.

2. Carefully remove the clasp (1) using the enclosed screw-

driver. The pressure spring (2) pushes out ball (4) and

valve seat (5).

3. Clean or replace the components.

4. Check the O-ring (7) for damage.

5. Check the installation position when mounting the spring

support ring (3) (clipped onto spring (2)), outlet valve seat

(5) and seal (6), refer to figure.

Please also pay particular attention to the following notes:

1. The torque for fitting the outlet valve is 50 Nm.

2. Always also replace the seal (6) if you have dismantled the

outlet valve, regardless of which component you want to

replace. Note: The seal (6) is located inside the paint sec-

tion.

3. The groove in the seal (6) points outwards when replaced.

1

7

2

3 4

5 6

3

4

5

6

7

10 (15 Nm)

SETTING THE MAXIMUN OPERATING PRESSURE

(CLOSING PRESSURE)

1. Lock the spray gun.

2. Set pressure relief valve to

, switch on the machine and

let it run for 2-3 minutes for ventilation. Turn the pressu-

re regulation screw (6) slowly until the machine starts to

suck in water.

3. Set pressure relief valve to

and trigger spray gun for

ventilating high pressure hose and spray gun. Lock the

spray gun .

4. Turn the pressure regulation screw (6) slowly until the

pressure gauge shows 250 bar (25 MPa, 3625 psi); Japan

210 bar (21 MPa).

5. Put pressure regulation knob (5) on the pressure regu-

lation screw and fully turn it to the right. Hold it in this

position and tighten the pin (7) with a hexagonal wrench

(2.5 mm).

6. Turn pressure regulation knob to the left.

7. Release pressure by pressing the trigger of the the spray

gun.

8. Control setting while the gun is locked again.

9. Seal pin with red sealing wax.

10. Set pressure relief valve to

.

11. Machine is ready for operation!

GB