41

12

.

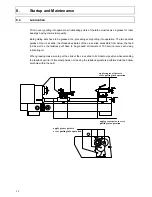

Angle plate with milling table

for drilling and milling

The milling is used to produce flat surfaces and

grooves. When milling the advance and feed motion

are effected with the angle plate from the workpiece.

If the angle plate is correctly mounted on the

compound rest (see assembly instructions), the

workpiece can be rigidly and firmly attached to the

clamping plate. This should be cleaned of dirt and

chips beforehand in order to guarantee a good rest.

The clamping screws used are inserted into the T-

groove of the clamping plate. In addition, a machine

vice can be attached to the clamping plate. The tool is

to be clamped as short as possible in the collet chuck

(danger of breaking). If the tool is firmly clamped, the

depth adjustment can be made over the feed shaft.

Assembly of the angle plate with the milling table

At first you remove the longitudinal slide rest from the transversal slide rest of the lathe. Then the

angle is screwed on to the carriage of the transversal slide rest with the delivered hexagon screw.

After removing the clamping plate and the spring from the longitudinal slide rest you fix the

longitudinal slide rest as indicated against the clamping angle.

Содержание D2000E

Страница 11: ...11 2 Drawings and list of parts 2 2 Support with motor and protective cover for D2400 E and D3000 E ...

Страница 13: ...13 2 Drawings and list of parts 2 3 Leading spindle drive for D2000 E and D2400 E ...

Страница 17: ...17 2 Drawings and list of parts 2 5 Leading spindle drive with gear motor for D2000 E ...

Страница 19: ...19 2 Drawings and list of parts 2 6 Cross table ...