29

8.

Startup and Maintenance

8.5

Initial cleaning of the machine

Prior to putting the machine into operation for the first time all maked parts have to be cleaned

applying petroleum or gasoline used for cleaning, because these parts have been treated with

slushing oil before leaving the factory.

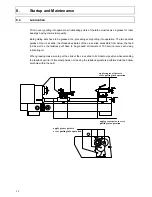

8.6 Spindle

head

The spindle head is firmly attached to the slide bars. In the spindle head, the work spindle is run on

two adjustable precision tapered roller bearings.

adjustment nut

ON -OFF lever

for automatic feed

Should a readjustment of the bearings be neccessary, please proceed in the following

manner:

1. Loosen the locking screw in the adjustment nut. The adjustment nut is located at the rear end of

the work spindle.

2. Turn the adjustment nut in a clockwise direction until the bearings again run free of play (the

work spindle being easily able to be turned by hand).

3. Tighten the locking screw again.

i

Roller bearing adjusted too tightly become useless after a short period

Automatic feed:

Likewise, the is an on-off lever for the automatic forward feed on the front side of the spindle head.

When supplied the wheels for the forward feed 0.085 mm/rev. are attached.

Содержание D2000E

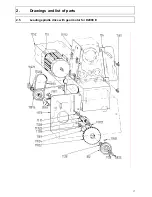

Страница 11: ...11 2 Drawings and list of parts 2 2 Support with motor and protective cover for D2400 E and D3000 E ...

Страница 13: ...13 2 Drawings and list of parts 2 3 Leading spindle drive for D2000 E and D2400 E ...

Страница 17: ...17 2 Drawings and list of parts 2 5 Leading spindle drive with gear motor for D2000 E ...

Страница 19: ...19 2 Drawings and list of parts 2 6 Cross table ...