30

8.

Startup and Maintenance

8.7 Compound

rest

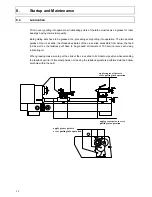

The compound rest consists of a longitudinal and a transverse slide rest.

Its dovetail guides are

ajustable.

counter nuts

longitudinal slide

counter nuts

transverse

hexagon socket screw

for tightening the

compound rest

take-up screw +

take-up screw +

8.7 Compound

rest

Should a readjustment be necessary, please proceed in the following manner:

1. Counter nuts must be loosened.

2. By using a socket head wrench, tighten the readjustment screws until the carriage can just be

turned to and from by means of the crank.

3. adjustment tighten the counter nuts again.

Longitudinal slide:

The longitudinal slide rest is mounted on the transverse slide rest and can be pivoted through 360°

degrees. Thus, it is suitable for the

turning of tapers

. For adjustment, the 4 mm Allen key is used

to loosen the two screws located on the outer sides of the transverse slide rest. The arrow on the

transverse slide rest. There is a scale of the degrees on the longitudinal slide rest. The distance

between two graduation marks represents one degree.

Scale rings:

To set the turning tools, the slide rest spindles have graduation collars with graduation marks. One

graduation mark represents a

0.05 mm

feed adjustment which corresponds to a 0.1 mm chip

removal on the work piece.

The hexagon socket screw is provided for cases where the compound rest is to be fixed to the slide

bars (e.g. in the case of transverse turning.) It screws down the clamped piece at the lower side of

the transverse slide rest against the two slide bars.

Содержание D2000E

Страница 11: ...11 2 Drawings and list of parts 2 2 Support with motor and protective cover for D2400 E and D3000 E ...

Страница 13: ...13 2 Drawings and list of parts 2 3 Leading spindle drive for D2000 E and D2400 E ...

Страница 17: ...17 2 Drawings and list of parts 2 5 Leading spindle drive with gear motor for D2000 E ...

Страница 19: ...19 2 Drawings and list of parts 2 6 Cross table ...