14

3. Through the oil fill hole, refill the reservoir with SAE-20 or SAE-30 (API CG/CD

heavy duty), non-detergent compressor oil. For extreme winter conditions, use

SAE-10 weight

4. Fill to the red dot in the oil level sight glass. Do not over-fill.

5. Replace the oil fill plug.

CAUTION

!

l

All air line components (including hoses, pipe, connectors, filters, & regulators,

etc.) must be rated for a minimum working pressure of 150 psi or 150% of the

maximum system pressure, whichever is greater.

l

Disconnect any tools from the air supply before performing maintenance,

clearing a jammed fastener, leaving the work area, moving the tool to another

location, or handing it to another person.

l

When cleaning air filter, or any parts in direct contact with the air production, do

not use any flammable or toxic cleaner or solvent.

l

During the break-in period, nuts and bolts have a tendency to loosen up. After

two weeks, tighten all nuts and bolts including head bolts.

GENERAL MAINTENANCE

l

Keep the vents and cooling vanes clear of dust and debris. This will help

prevent possible electrical shorts and ensure proper cooling.

l

Inspect the cord regularly and have it replaced by an authorized repair facility if

it is damaged.

l

Check the tanks regularly for dents, cracks, rust, and other damage. Do not use

if any part of the pressurized system is damaged.

l

An authorized repair center should do any repairs, modification, or maintenance

that involve disassembling the compressor.

l

Please call toll-free 1-800-482-0131 with any questions you have or service

advice you may need.

Содержание 650-4815

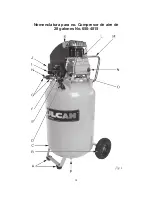

Страница 6: ...6 Nomenclature for No 650 4815 28 gal Air Compressor...

Страница 24: ...24 Nomenclatura para no Compresor de aire de 28 galones No 650 4815...

Страница 44: ...44 Nomenclature pour no 650 4815 Compresseur d air 28 gallons...

Страница 58: ...58 SCHEMATIC DRAWING ESQUEMA SCH MA 650 4815 v 090928...