7-6

P24AL & P34AL Service Manual

MAINTENANCE

12/2016

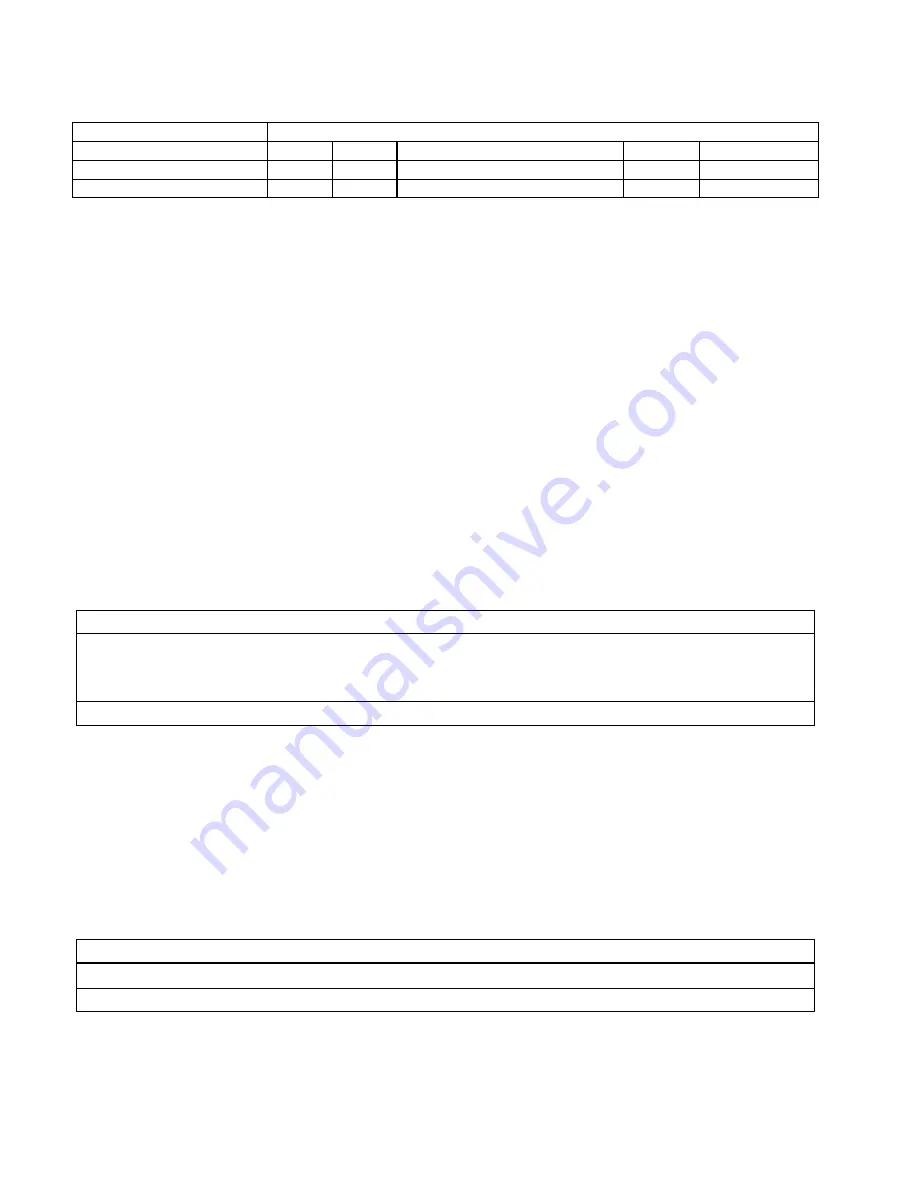

Frequency

1st

2nd

3rd

4th

Thereafter

Change oil

200 hr.

500 hr.

1500 hr.

4000 hr.

every 4000 hrs.

Clean suction strainer cloth

200 hr.

500 hr.

Remove if clogging is minimal

Table 7-4

Compressor Maintenance

The above maintenance is only a guide. The compressor should be inspected anytime there is

unusual noise, damage is suspected or the oil becomes discolored. The oil should be changed any

time the compressor is opened. For specific recommendations and instructions, refer to the

particular compressor manufacturer’s manual. See “Compressor Oil Changing and Inspection”

Oil Trap.

Although the compressor is equipped with an oil separator, which has an automatic

return, some oil will pass through the separator and eventually settle in the oil trap (36), which is

offset from the base of the freezer. This oil trap will have evidence of frost on its surface during the

freeze cycle and may be more pronounced at the end of a normal freeze cycle just before the harvest.

Where there is oil in the trap, there will not be frost. Where there is frost, there will not be oil.

When the trap is 1/2 to 3/4 full of oil, it should be drained.

The machine should be shutdown for at least 12 hours before attempting to drain oil from the trap.

Follow the procedure outlined in the service section, “Draining Oil Trap”.

! CAUTION !

Only qualified refrigeration service personnel familiar and

experienced in the handling and use of anhydrous ammonia (R717) should be

authorized to perform the “Draining Oil Trap” procedure.

! CAUTION !

Cutter Gear Reducer.

The oil level of the gear reducer should be checked monthly or when there is

any evidence of leakage. The correct level is indicated by the pipe plug in the side of the gear

housing. The oil should run out of the hole when the plug is taken out. If low, add oil through one

of the top plugged holes. A high grade lubricant such as Mobil 600W or SAE 140 gear oil should be

used. The oil should be changed annually. Drain the oil and flush the gear case with mineral spirits.

Drain the mineral spirits completely and refill with the proper oil.

Note: If a USDA high food grade lubricant is desired, use Chevron FM Lubricating Oil 460X.

! CAUTION !

Follow all lock-out and tag-out procedures before servicing any electrical equipment.

! CAUTION !

Содержание P-24AL

Страница 1: ...12 2016 P 24AL P 34AL TUBE ICE MACHINE Service Manual 5000 ...

Страница 10: ...P24AL P34AL Service Manual TABLE OF CONTENTS 12 2016 vi ...

Страница 14: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 4 Figure 1 1 P24AL 1 Front Side Control Panel ...

Страница 15: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 5 Figure 1 2 P24AL Right Side ...

Страница 16: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 6 Figure 1 3 P24AL Back Side ...

Страница 17: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 7 Figure 1 4 P24AL Left Side ...

Страница 18: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 8 Figure 1 5 P34AL Front Side Control Panel ...

Страница 19: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 9 Figure 1 6 P34AL Right Side ...

Страница 20: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 10 Figure 1 7 P34AL Back Side ...

Страница 21: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 11 Figure 1 8 P34AL Left Side ...

Страница 22: ...P24AL P34AL Service Manual INTRODUCTION 12 2016 1 12 ...

Страница 28: ...P24AL P34AL Service Manual INSTALLING YOUR TUBE ICE MACHINE 12 2016 3 4 Figure 3 2 P24AL Foundation Layout ...

Страница 31: ...P24AL P34AL Service Manual INSTALLING YOUR TUBE ICE MACHINE 12 2016 3 7 Figure 3 4 P34AL Foundation Layout ...

Страница 32: ...P24AL P34AL Service Manual INSTALLING YOUR TUBE ICE MACHINE 12 2016 3 8 Figure 3 5 Lifting Procedure for P24AL ...

Страница 33: ...P24AL P34AL Service Manual INSTALLING YOUR TUBE ICE MACHINE 12 2016 3 9 Figure 3 6 Lifting Procedure for P34AL ...

Страница 53: ...P24AL P34AL Service Manual HOW YOUR TUBE ICE MACHINE WORKS 12 2016 4 3 Figure 4 1 Piping Schematic for P24AL ...

Страница 54: ...P24AL P34AL Service Manual HOW YOUR TUBE ICE MACHINE WORKS 12 2016 4 4 Figure 4 2 Piping Schematic for P34AL ...

Страница 62: ...P24AL P34AL Service Manual START UP OPERATION 12 2016 5 8 ...

Страница 84: ...P24A P34A Service Manual TROUBLESHOOTING 12 2016 8 12 ...

Страница 97: ...P24AL P34AL Service Manual SERVICING OPERATIONS 12 2016 9 13 Figure 9 5B P24A Water Tank Assembly ...

Страница 110: ...P24AL P34AL Service Manual SERVICING OPERATIONS 12 2016 9 26 ...

Страница 126: ...P24AL P34AL Service Manual TABLES CHARTS 12 16 16 11 8 ...

Страница 130: ...P24AL P34AL Service Manual INDEX 12 2016 12 4 ...

Страница 131: ...Appendix A ...

Страница 134: ......

Страница 136: ...i ...

Страница 137: ...ii ...

Страница 138: ...1 ...

Страница 139: ...2 ...

Страница 140: ...3 ...

Страница 141: ...4 ...

Страница 142: ...5 ...

Страница 143: ...6 ...

Страница 144: ...7 ...

Страница 145: ...8 ...

Страница 146: ...9 ...

Страница 147: ...10 ...

Страница 148: ...11 ...