Possible causes for low UV alarm conditions:

a) The UV lamps have perhaps reached a level whereby they can no longer adequately

provide a sufficient level of disinfection due to age (> 9000 hours). The lamps

should be replaced with new lamps from the manufacturer of the same size and

type.

b) The quartz sleeves and/or the sensor window have become stained or dirty.

Mineral deposits or sediment in the water that was not detected during the original

water analysis may be the cause for this (refer to page 9 for cleaning instructions).

c) Intermittent voltage drop in the line power supply reducing the lamp output. The

lamp will return to normal when the power is restored to full voltage.

Note: the

monitoring system will not operate during power failures.

d) The quality of the influent water has changed and is no longer within the

acceptable operational range of the UV system. Perform a water analysis to

determine the exact constituents and concentration levels.

e) The UV sensor is not installed correctly (see page

10

).

2. Lamp life remaining (days):

To obtain this reading, press the push-button SWITCH a single time and follow the

steps as outlined on page

11

, regarding the operation of this feature.

3. Total days of operation:

To obtain this reading, press the push-button SWITCH two times in succession and

follow steps as outline on page

11

, regarding the operation of this feature.

4. Lamp failure (blank screen):

Please refer to page

10

for explanation of this feature.

Note:

On the Hi-Flo Monitored systems, the audible tone provided for lamp failure is

a continuous alarm, rather than the intermittent (1 second on, 1 second off)

condition on the basic Hi-Flo systems.

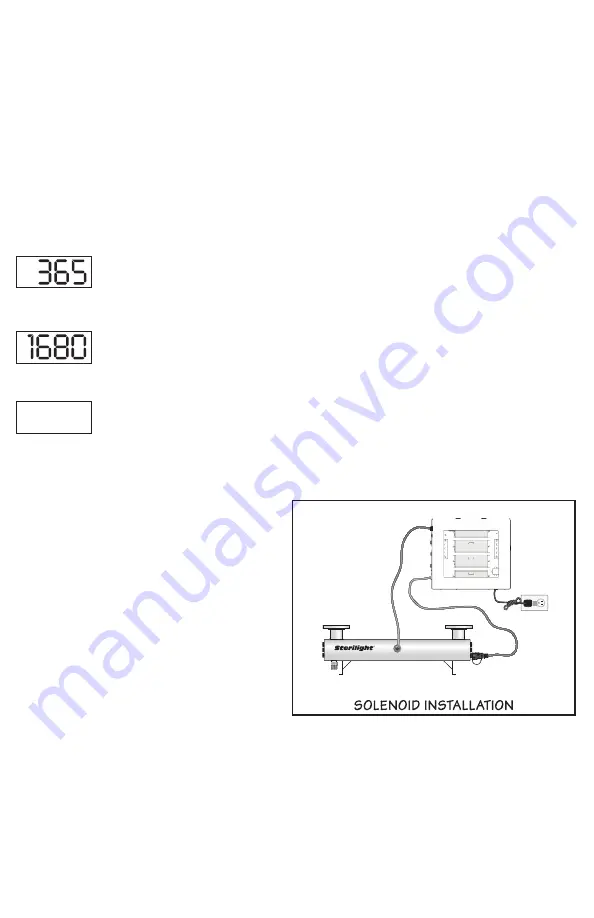

5. Solenoid Output:

Working in conjunction with the UV intensity

monitor, the Hi-Flo Monitored controller

provides a powered (line voltage) IEC

solenoid output connector. (Note: this is

not a dry contact) This solenoid output is

protected with a replaceable 2 amp isolated

fuse. Connection from this output to the

solenoid can be done using the IEC solenoid

power cable PN 260184-R. When the UV

intensity monitor senses that the water is

not adequately being treated and drops to

49% UV intensity or below, the internal relay

is opened thereby stopping AC power flowing to the normally closed solenoid valve.

The valve will remain closed (no power) until the UV level rises above

49%, at which time the solenoid will open, allowing for water to pass through.

(To temporarily enable the operation of this solenoid output for up to 12 hours,

please refer to the instructions outlined on page 12 of this manual).

13

SOLENOID TO BE

INSTALLED ON INLET

OR OUTLET

INLET/OUTLET

OPTIONAL

DRAIN COCK

INLET/OUTLET

STERILIGHT

HI-FLO

CUTOMER SUPPLIED

GFCI CIRCUIT

TO MATCH VOLTAGE

HF