- 10 -

6. Parameter Programming

1) Press and hold the

SET

+

keys until the “

°C” or “°F”

LED starts flashing,

then release the keys.

2) Press and hold again the

SET

+

keys until the

Pr2

label is displayed, then

release the keys. The first parameter

Hy

will be displayed.

3) Press up/down keys

/

to scroll to the required parameter within 10 sec.

4) Press the “

SET

” key to display its value.

5) Use up/down keys

to change its value within 10 sec.

6) Press “

SET

” to store the new value and the display will flash 3 times.

7)

To exit

: Press

SET +

or wait 15sec without pressing a key.

PARAMETER DESCRIPTION

DEFAULT

VALUE

Set

set-point (

°

)

55

Hy

temperature regulation differential

(

°

)

4

AC

anti-short cycle delay (min)

10

Con

compress on with probe faulty (min)

20

CoF

compress off with probe faulty (min)

20

CF

temperature unit

(

°

F

/ °

C

)

F: Fahrenheit

rES

display resolution

in: integer

dLy

temperature display delay (min)

1

ot

probe calibration

(

°

)

0

LS

minimum set-point

(

°

)

50

US

maximum set-point

(

°

)

65

idF

defrost cycle interval time (hour)

12

MdF

defrost cycle endurance time (min)

30

ALC

temperature alarm type

rE: relative to set-point

ALU

high temperature alarm

(

°

)

10

ALL

low temperature alarm

(

°

)

10

AFH

alarm recovery differential

(

°

)

5

ALd

temperature alarm delay (min)

60

dAo

temperature alarm delay on startup (hr)

23

SAA

heater set-point

(

°

)

40

SHy

heater regulation differential

(

°

)

4

FSU

fan action

Std

FnC

fan operating mode

C-n: on with compressor & off during defrost

C-y: on with compressor & on during defrost

O-n: on all the time & off during defrost

O-y: on all the time & on during defrost

Fon

fan on with compressor off (min)

0

FoF

fan off with compressor off (min)

15

NOTE

: Depending on the controller, not all parameters are used.

Содержание Wine-Mate WM-4510HZD

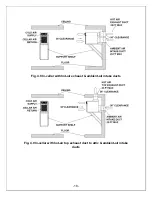

Страница 24: ...23 Fig 4 15 Cold air supply cellar air return and hot air exhaust ducts...

Страница 29: ...28 Electrical Wiring Diagrams Fig 7 1 WM 4510 8510HZD standard wiring diagram...

Страница 30: ...29 Fig 7 2 WM 4510 8510HZD crankcase heater wiring diagram...

Страница 31: ...30 Fig 7 3 WM 4510 8510HZD alarm call wiring diagram...

Страница 32: ...31 Fig 7 4 WM 4510 8510HZD cellar heater wiring diagram...

Страница 33: ...32 Fig 7 5 WM 4510 8510HZD crankcase heater alarm call wiring diagram...

Страница 34: ...33 Fig 7 6 WM 4510 8510HZD crankcase heater cellar heater wiring diagram...

Страница 35: ...34 Fig 7 7 WM 4510 8510HZD alarm call cellar heater wiring diagram...

Страница 36: ...35 Fig 7 8 WM 4510 8510HZD crankcase heater alarm call cellar heater wiring diagram...