15

5285 429 - 03

Vitorond 200, VD2 Series 320 to 1080 Installation

Cast Iron Section Assembly

(continued)

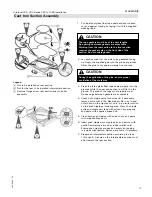

Assembly

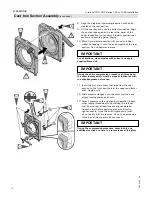

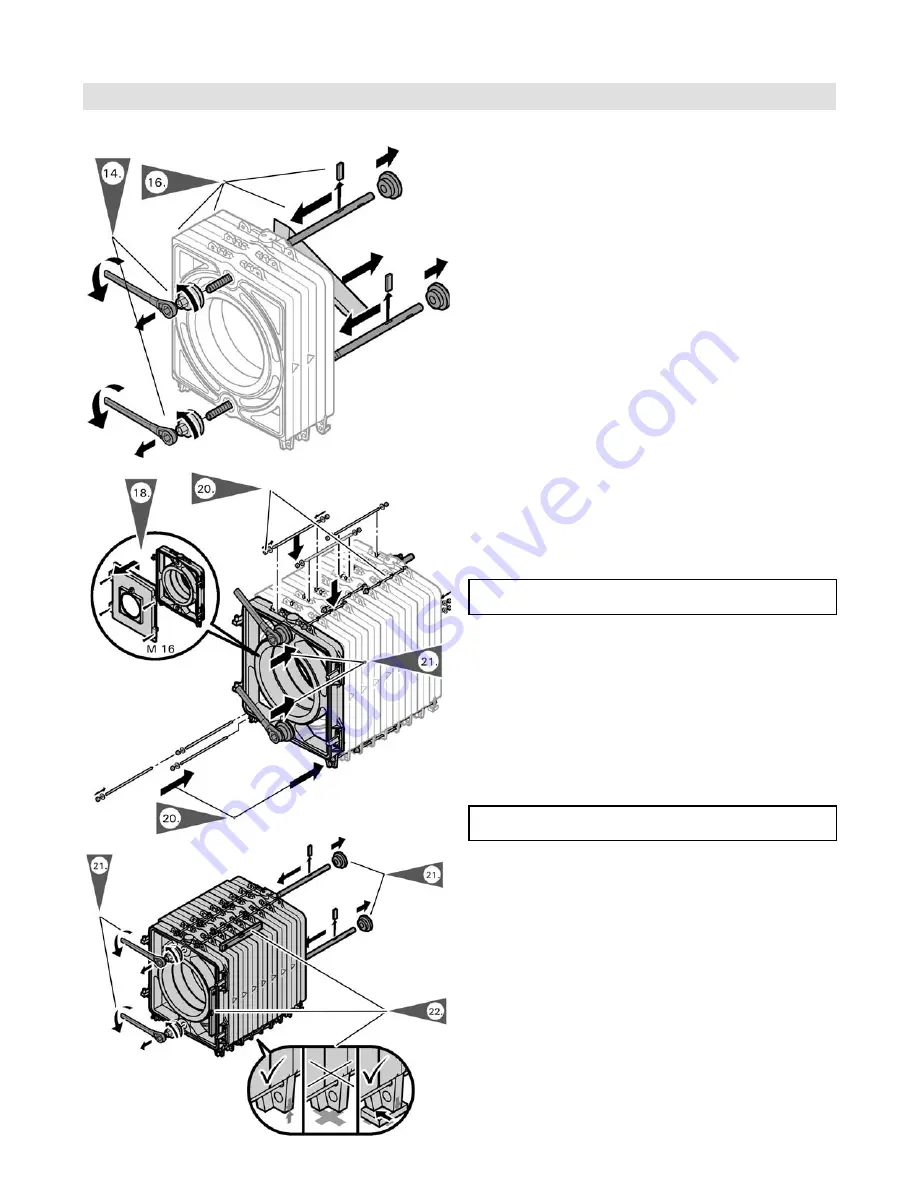

14. Loosen draw tool and remove pressure nuts.

15. Repeat steps 1 through 10 until the draw tool kit can

be used again. Do not glue glass fiber rope into center

of pre-cast groove of intermediate section attached

to front section (see page 10).

16. Attach extension rods to the main draw rods and

sections according to steps 11 and 12, until heat

exchanger block is completely assembled.

17. Remove supports after three sections have been

assembled.

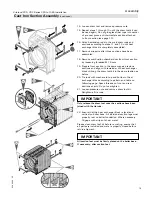

18. Remove combustion chamber door from front section

by loosening threaded M 16 nuts.

19. Prepare front section in the same way as previous

sections and align with remainder of heat exchanger

block utilizing the draw tool kit in the same fashion as

before.

20. Tie rods with washers to top and bottom of heat

exchanger block according to pattern and table on

following page. Space threads on front and rear

sections evenly. Do not overtighten.

21. Loosen pressure nuts and remove draw tool kit.

Retighten all tie rods.

IMPORTANT

Only release the draw tool once the sections have been

joined with the tie rods.

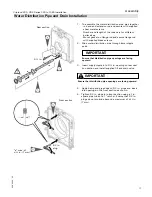

22. Ensure that the heat exchanger block is level and

vertical on boiler base. All individual section legs must

properly rest on boiler foundation. Where necessary,

fill gaps with strips of sheet metal.

Please clean draw tool kit before re-crating, ensure that

all parts are included and crate is properly closed before

return shipment.

IMPORTANT

All section feet must be firmly placed on the boiler base.

If necessary, shim section feet.