19

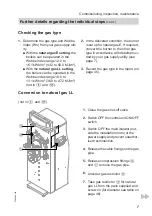

Checking both gas train valves for tightness

A

B

1.

Close the gas shut-off valve.

2.

Undo the screw inside test nipple

B

for supply pressure, but do not

remove.

3.

Undo the screw inside test nipple

A

, but do not remove.

4.

Connect the pressure tester with the

manual pump to test nipple

A

.

5.

Gently activate the manual pump to

build a test pressure of approx.

50 mbar.

6.

Wait approx. 5 min for the tempera-

ture to level out and then observe the

display on the pressure tester:

If the displayed pressure does not

drop by more than 1 mbar within

5 min, then the gas train is tight.

Otherwise there is a leak. If this is the

case, return the gas train to

Viessmann Werke for testing.

7.

After the test, close both test nipples

by tightening the relevant screws.

Danger

Escaping gas leads to a risk of

explosion.

Check the test nipple for gas

tightness.

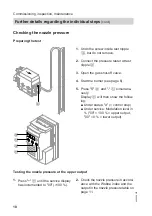

Checking all gas connections for tightness

Danger

Escaping gas leads to a risk of

explosion.

Always carry out the following

steps.

1.

Insert new gaskets in all gas connec-

tions that have been opened and

tighten afterwards.

2.

Open the gas shut-off valve.

3.

Check the inlet seals of the gas train

for tightness.

4.

Start the burner (see page 6).

5.

Check the seals on the outlet side of

the gas train for tightness.

Commissioning, inspection, maintenance

Further details regarding the individual steps

(cont.)

5692 488 GB