37

VE414

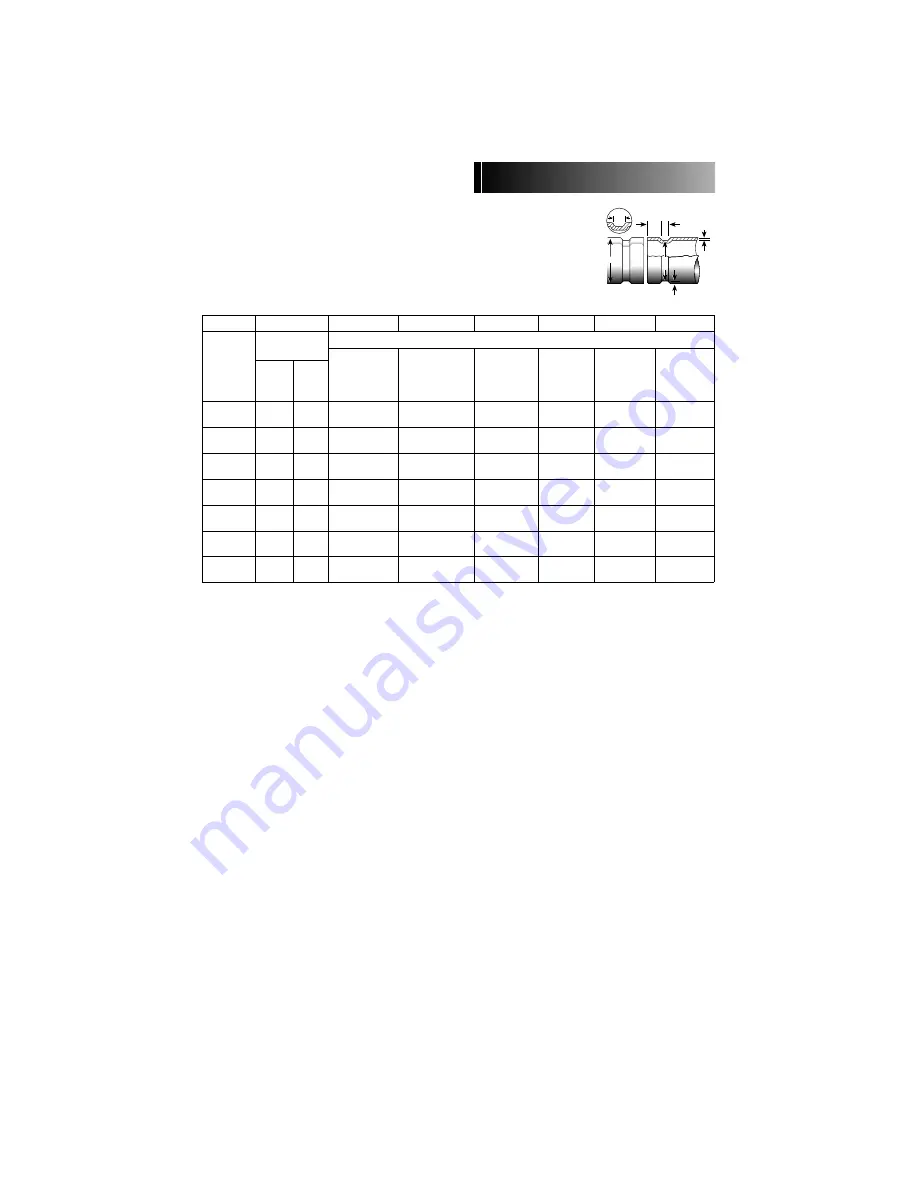

DRAWN COPPER TUBING

25.06-1A

1

2

3

4

5

6

7

8

SIZE

Nominal

Inches

Actual

mm

Pipe O.D.

Inches/

mm

Dimensions – Inches/

millimeters

Gasket Seat

A

±0.03/

±0.76

Groove Width

B

+0.03/-0.00

+0.76/-0.00

Groove

Diameter

C

+0.00

Groove

Depth

(ref.)

D

Min.

Allow.

Wall Thick.

T

Max.

Allow.

Flare Dia.

Basic

Tol.

2

2.125

±0.002

0.610

0.300

2.029

0.048

0.064

2.220

60.3

54.0

±0.05

15.5

7.6

51.5

1.2

1.6

56.4

2

¹⁄₂

2.625

±0.002

0.610

0.300

2.525

0.050

0.065

2.720

73.0

66.7

±0.05

15.5

7.6

64.1

1.2

1.7

69.1

3

3.125

±0.002

0.610

0.300

3.025

0.050

DWV

3.220

88.9

79.4

±0.05

15.5

7.6

76.8

1.2

81.8

4

4.125

±0.002

0.610

0.300

4.019

0.053

DWV

4.220

114.3

104.8

±0.05

15.5

7.6

102.1

1.4

107.2

5

5.125

±0.002

0.610

0.300

4.999

0.053

DWV

5.220

141.3

130.2

±0.05

15.5

7.6

127.0

1.4

132.6

6

6.125

±0.002

0.610

0.300

5.999

0.063

DWV

6.220

168.3

155.6

±0.05

15.5

7.6

152.3

1.6

158.0

8

8.125

*

0.610

0.300

7.959

0.083

DWV

8.220

219.1

206.4

*

15.5

7.6

202.2

2.1

208.8

*Tolerances for 8" (219.1 mm) are + 0.002 (0.5 mm) –0.004 (–.10 mm).

COPPER TUBING ROLL SPECIFICATIONS NOTES

COLUMN 1:

Nominal ASTM B-88 drawn copper tubing size.

COLUMN 2:

Outside diameter –

The outside diameter of roll grooved tubing shall not vary more than the tolerance listed. The

maximum allowable tolerance from square cut ends is 0.030" (0.8 mm) for 2 - 3" (60.3 - 88.9 mm); 0.045" (1.1 mm) for 4 - 6"

(114.3 - 168.3 mm), measured from true square line.

COLUMN 3:

Gasket seat –

The tubing surface shall be free from indentations, roll marks, and projections from the end of the tubing

to the groove, to provide a leak-tight seat for the gasket. All loose scale, dirt, chips and grease must be removed.

COLUMN 4:

Groove width –

Bottom of groove to be free of loose dirt, chips and scale that may interfere with proper coupling as-

sembly.

COLUMN 5:

Groove outside diameter –

The groove must be uniform depth for the entire tubing circumference. Groove must be

maintained within the “C” diameter tolerance listed.

COLUMN 6:

Groove depth –

For reference only. Groove must conform to the groove diameter “C” listed.

COLUMN 7:

ASTM B-306 –

Drain waste and vent (DWV) is minimum wall thickness copper tubing which may be roll grooved.

COLUMN 8:

Maximum allowable end flare diameter –

Measured at the most extreme tubing end dia.

A B

OD

C

B

D

T