NOTICE!

Avoid pulling the coupling out abruptly to the end stop, as the

retainer or the pull-out protection can be damaged if you do so.

5.

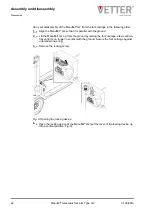

Align the boreholes in the slip-on coupling and the basic fork arm (Fig. 12).

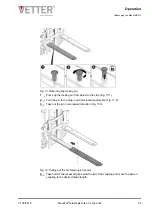

Fig. 13: Inserting the locking pin

6.

Align the lateral stud of the locking pin with the corresponding groove in the bore-

hole. Insert the locking pin in the lock borehole (Fig. 13/1).

7.

Turn the locking pin in a clockwise direction to a fixed stop (Fig. 13/2).

8.

Press down the locking pin and countersink it completely in the basic fork arm (lock

5.2

Adjusting the fork arm spacing

Personnel:

n

Driver of industrial trucks

Protective equipment:

n

Protective work clothing

n

Industrial helmet

n

Protective gloves

n

Safety shoes

Operation

Adjusting the fork arm spacing

V1.09/2019

ManuTel

®

telescopic fork arm Type G2

26

Содержание ManuTel G2 MTGZ16/10/16/A

Страница 2: ...V1 09 2019 ManuTel telescopic fork arm Type G2 2 ...

Страница 39: ...Own notes Technical data V1 09 2019 ManuTel telescopic fork arm Type G2 39 ...

Страница 40: ...Technical data V1 09 2019 ManuTel telescopic fork arm Type G2 40 ...

Страница 42: ......