Operation - 29

GENERAL OPERATION

Daily Inspection

1.

Always set the parking brake, shut off power

unit engine, remove the ignition key, and ensure

all moving parts have come to a complete stop

before inspecting components, or attempting

any repair or adjustment.

Park machine on a level surface, with the engine

shut off and all fluids cold.

2. Perform a visual inspection of both the power

unit and the weather cab. Ensure the weather

cab is properly mounted to the power unit. Look

for loose or missing hardware, damaged com-

ponents, or signs of wear.

3. Check the power unit’s lights along with work

lights, hazard lights, and/or strobe light to

ensure lights are working properly.

4. Inspect window and door seals for cracks and

tears. Check glass for chips or damage.

5.

Inspect hydraulic hoses and fittings, fuel lines, and

heater lines to ensure tight, leak free connections.

6. Refer to the power unit operator’s manual.

Check the power unit’s engine oil, hydraulic oil,

cooling system, tire pressure, and fuel level. Add

fluid or service as required.

7. Repair or replace damaged or non-working

components.

8. Check the windshield wiper blade condition.

Clear any ice or snow from the wiper before

use. If blade is frozen to the windshield, care-

fully loosen or thaw the blade.

9. Clear any ice or snow from the windows and/or

defrost the windows before use. Do not operate

if visibility is restricted.

10. Test the power unit’s operator safety interlock

system*.

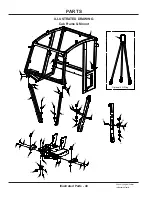

4-Point Seatbelt

Fasten the lower buckle of the 4-point seatbelt and

adjust the lap belt until snug but not tight. Tighten by

pulling bon the ends of the lap belt straps. Tighten

both sides evenly so the buckle remains centered

on the operator. Loosen by pulling up on the edge of

the seatbelt strap lock facing away from the buckle.

Upper buckle

location

Pull strap to

tighten

Lift up on tab

to release

Fasten the upper buckle of the 4-point seatbelt and

adjust the left and right shoulder belts. The shoulder

belts should be loose enough to allow the operator

to reach all dash controls, but should be snug at the

point that the operator can reach the dash controls.

Tighten the left and right shoulder belts by pulling on

the ends of the straps. Loosen the shoulder belts by

lifting up on the tab on the seatbelt strap lock

Adjust the upper buckle location so that the buckle

catches the operator in the middle of the chest when

the operator leans forward against the belt.

If the seatbelt cannot be tightened or loosened far

enough to properly fit the operator, the seatbelt

upper mount will need to be adjusted. Refer to seat-

belt upper mount adjustment in the service section

of this manual.

Strobe Light

The strobe light is mounted on a pivoting arm.

Rotate the strobe light up during operation. Rotate

the strobe light back and down for low clearance

areas, transport, or storage.

The strobe light arm is held in place by a spring. If

the strobe light or arm contacts an object, the spring

releases the pivot arm to rotate either forward or

backward away from the object. If this occurs, stop

operation and return the strobe light to the operating

position when clearance allows.

* Refer to power unit operator’s manual for operation of

power unit controls.