Wanner Engineering, Inc.

4

United States

Instant Information: www.vectorpump.com

(61) 33-5681 Fax (61) 33-6937 VEC-991-400A

Replacing Worn Hose

Remove Old Hose

1. Turn off and lock out all power to pump motor.

2. Remove front cover from pump (four screws).

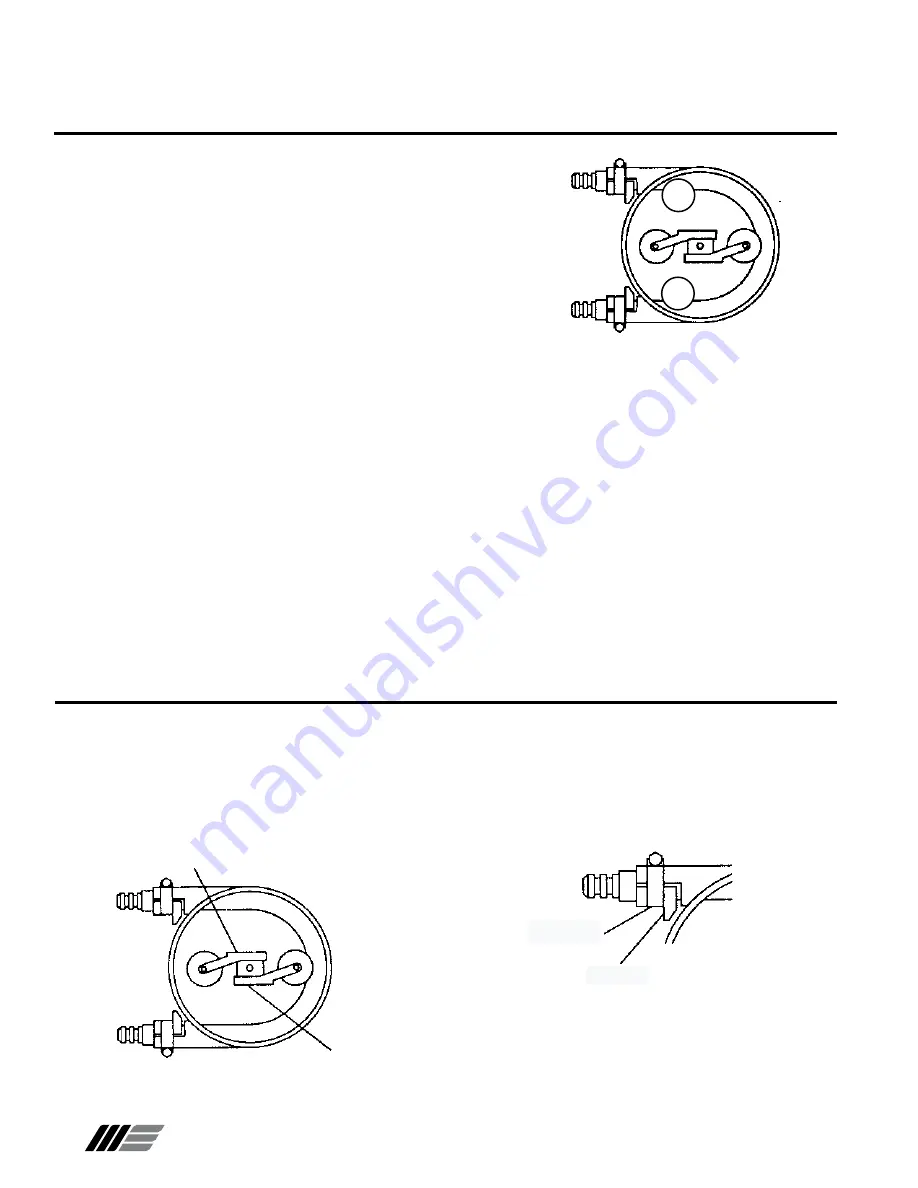

3. See Figure 4. Position pressure rollers as shown.

4. Loosen screw(s) that secure mounting bracket of pressure

roller which is compressing hose. To maintain correct hose

compression adjustment,

DO NOT

loosen opposite roller’s

mounting bracket.

5. See Figure 5. Loosen hose clamp bolts. Remove hose

supports and clamps that secure both ends of hose.

6. Remove hose from pump casing.

Service (Models 2002, 2003, 2004, 2005)

Vector Series Installation

Troubleshooting

If the hose fails prematurely, check for:

• Chemical attack. If the hose becomes soft, spongy, or harder

than when originally supplied, chemical attack may be the

problem.

• Improper hose selection for the fluid being pumped.

• Improper roller setting. If flow fluctuates back and forth or up

and down in the discharge line, the rollers may not be adjusted

with equal pressure on the hose.

• See Figure 3. If the hose fails in area A, this may occur from

operating the pump at a discharge pressure higher than the

hose is rated for, or with a closed discharge line. If the hose

fails in area B, this may occur from operating the pump under

a higher vacuum or higher inlet pressure than the hose is

rated for, or with a closed suction line.

• Line system problems — debris, closed valves, or a clogged

or packed line.

• Fluid temperature too high.

• Abrasive material being pumped, or solid size too large.

• Hose connector becomes loose:

- Wrong size connector.

- Suction pressure too high

W0458

Loosen screw(s) that

secure this bracket.

Do not

loosen screw(s)

for this bracket.

Figure 4

W0456

DISCHARGE

INLET

A

B

Figure 3

Hose Support

Hose Clamp

W0459

Figure 5

7. Pull (cut hose if needed) hose connectors from worn hose.

Clean if reusable.

8. Carefully clean pump casing and front cover.

Routine Maintenance

Periodically inspect hose for signs of failure caused by chemical

attack, material fatigue, etc.

Check non-petroleum silicone lubricant on hose, and reapply

if worn off.

Inspect roller bearings for damage, and replace if necessary

(See Parts List, item 11).

Check that all fasteners are properly tightened.