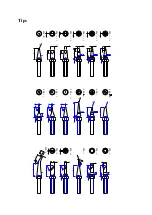

1.

Turn the nut

①

anticlockwise and remove the tip enclosure

②

and the tip

③.

2.

Turn the nipple

④

anticlockwise and remove it from the iron.

3.

Pull Heating Element

⑩

out of Handle

⑦

. (Toward the tip of the iron).

4.

Do not use metal tools such as pliers to remove tip or Tip enclosure from the handle.

Measure when the heating element is at room temperature:

1.

Resistance value of heating element (white) under 1

Ω.

2.

Resistance value of sensor (Red and Green ) under 10

Ω.

If the resistance value is not normal, replace the heating element. After replacing heating

element, please check as follow.

1.

Measure the resistance value between pins 4&1 or 2, pins 5&1 or 2, pins 6&1 or 2, pins

6&4 or 5. If it is not

∞

, the heating element and sensor are touching. This will damage

the P.W.B.

2.

Measure the resistance value ‘a’,’b’, and ‘c’ to confirm that the lead wire are not twisted

and that the grounding wire is properly connected.

3.

To confirm that the clasp

⑨

is clasped with heating element

⑩

.

Item No.

Part Name

Instruction

1

Nut

2

Tip Enclosure

3

Soldering Tip

Refer to the last page

4

Nip

Nipple

5

Cord Cover

6

Handle Cover

7

Handle

8

Terminal Board

9

Clasp

10

Heater Combination

11

Vibrator Switch

12

Pin 6 Connector

Metal