Temperature dropping:

Don’t press “*” knob, and press “

▼

” knob directly. If so, the setting temperature will drop

1

℃

and the display window will display the set temperature. When loose the “

▼

” knob, the

display window will relay the set temperature about 2 seconds. If within 2 seconds , press the

“

▼

” knob again, the setting temperature will drop 1

℃

again. If press the “

▼

”knob and not

loose at least 1 second, the setting temperature will drop rapidly. Till the needed temperature

reaches, then loose the “

▼

” knob.

SECTION 10 Set Password

The initial password in station

’

s memory is “000”. The setting temperature is admitted in this

state. If need to restrict the setting temperature, the password must be changed

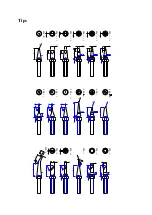

Enter into setting the password

1.

Turn off the power switch. Press and hold the

“

▲”

and

“▼

buttons simultaneously, then

turn on the power switch.

2.

Continue holding down the

“

▲”

and

“▼

”button until the display shows

.

3.

When the display shows

,the station is in parameter-input mode.

Input Previously Password

4.

Press the “*” button, the display shows

, and the left-most digit (the 100

’

s digit)

in the display will flash. This indicates the station is in password setting mode and the

100

’

s digit can be a

djusted.

Using the

“

▲”

or

“▼”

button will change displayed value. Set

the password value in the same way described in “set temperature normally”. After

selecting the password of three digit, press”*” button.

The input password is error

5.

If the display window shows the present setting temperature, two seconds later, the station

is in normal work state. This indicates the password of input is error, and the temperature

setting can

’

t be done.

The password of input is correct

6.

If the display window shows

, this indicates the password of input is correct.

After displaying about 4 seconds, the station comes into normal work state, and the

setting temperature will be admitted.