7

Värmebaronen Viking Bio 35

Installation

Downpipe

The downpipe is screwed to the body of the burner.

The downpipe can be rotated to obtain a suitable angle

to the feed auger.

Pellet store

Wood pellets must be stored in a dry, airy place protected

from the weather. Ready-made pellet stores are available

on the market. These are preferable to homemade stores.

It should be possible to remove the feed auger for cleaning

without having to empty the store.

The size of a weekly store depends on the building’s heating

requirements. However, we recommend that the store have

a volume of at least 500 litres.

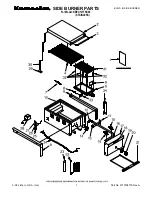

Feed auger

To guarantee that the correct quantity of pellets

is supplied, the burner must have one of the

appropriate feed augers.

Fit the feed auger motor on the feed auger. Tighten the

locking screw well so that the motor does not slip on the

feed auger shaft.

The feed auger must be well anchored with the chain as it

will work its way into the store.

Check the position of the feed auger before the store is filled

with pellets. Use tape or similar to mark on the feed auger’s

pipe how far it extends into the store. This makes it easy

to see whether the feed auger has worked its way into the

store and it becomes easier to refit the feed auger when it

has been taken out of a full store.

Use the enclosed hose to connect the feed auger to the

burner’s quick coupler on the downpipe. The hose must

have a straight fall without sudden bends and the hose

connections must be slightly displaced from each other.

Secure the hose at both ends with hose clips.

Connect the feed auger’s power cable to the power socket

on the burner.

Before starting the feed auger and the burner, the feed auger

must be filled with pellets. See ‘Startup’.

The inclination of the feed auger from the

horizontal plane must be 40°±5°.

40°±5°

H dimension at

40° inclination:

1,500 mm feed auger: 750 mm

2,500 mm feed auger: 1,400 mm

Risk of entrapment!

Before any work is done on the feed auger,

its power cable must be disconnected from

the burner.

Flue gas thermometer

The enclosed flue gas thermometer is fitted to the usual

connection on the boiler’s flue pipe.

Содержание Viking Bio 35

Страница 1: ...1 3 0 6 0 3 T H L n o 0 1 r e v 0 Installation and maintenance Viking Bio 35 pellet burner...

Страница 23: ......