Page 17

Complete Assembly

26) Remove the end cap and insert the body gasket/seal.

27) Recheck/re-inspect the sealing faces on ball, body and end cap to ensure they were not damaged

during handling.

28) Replace all damaged body studs. Apply Copper-Based Anti-Seize Grease high temperature com-

pound to the threads.

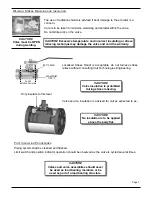

CAUTION! Never turn a nut more than ¼

turn with out moving to a different body nut.

NOTE:

THE STAR PATTERN IS EXTREMELY IMPORTANT.

33) Cycle the valve manually to verify that it is functioning correctly.

34) Re-torque the packing gland bolts evenly to the values given in Table 2.

32) During the entire initial pull-down the two faces should re-

main precisely parallel. Failure to do so may result in a faulty

seal. Torque in a star pattern to 1/3 of torque value listed in

Table 1. Then torque in a star pattern to 2/3 of torque value

listed in Table 1. Then repeat again at the full torque value of

Table 1. For valves larger than 10 inches, repeat the last

torque values (full torque).

31) Tighten the body studs/nuts evenly, observing the body gasket

pull-down. Using gradually increasing torque levels, tighten oppo-

site bolts using a

star-like pattern

until the body and end cap are

pulled face-to face

.

30) Insert the

new

ValvTechnolo-

gies body seal or gasket into the

body, being certain that the top

surface is precisely parallel with

the body face.

29) Replace Belleville spring,

upstream seat and ball.

Ensure the mate lapped side

is facing the end cap in the

valve body.