Page 15

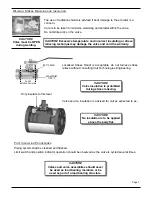

Lock-Up Gap for Large Bore Valves

16) Place the upstream seat into the valve body with radius facing the open-

ing, end cap end.

17) Insert the ball into the body, over the stem and onto the upstream seat.

18) Place the end cap carefully on the body and line up (parallel) with the

body. Measure the lock-up gap (seat/ball gap without a spring).

NOTE:

For small bore (5/8”, 1-1/16” and 2-1/8”),

low pressure (150# - 300#) valves, this measure-

ment is not taken directly, but is calculated after

measuring the spring standoff.

Lock-Up Gap

NOTE:

If this measurement cannot be taken directly

because of access, use alternative method, shown to the left.

Belleville Spring Standoff

19) Measure Belleville Spring height. Refer to Table 3, for acceptable height range. If height is out of

specification, replace with a new spring.

20) Remove the end cap,

ball and seat.

21) Insert the Belleville Spring with the

large end resting in the body pocket.

22) Insert the upstream seat

loose with the curved seat fac-

ing you, away from the Belle-

ville Spring.

Max. Feeler Gauge

Thickness (F)

Lock-Up Gap (With Gauge)

Gauge Height (T)

Body/End Cap

Gap (H)

Seat/Ball Gap = F x 1.4

(See Table 5 for limits)

Seat/Ball Gap = T– H

(See Table 5 for limits)

NOTE:

Some spring height is always lost due to “set” during first use. ValvTech-

nologies, Inc. recommends that the spring always be replaced during an overhaul.