Page 12

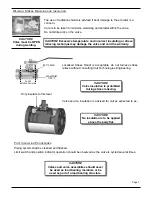

NOTE: If dimensions are not within this range, then ValvTechnologies, Inc. Engineering approval is required prior to assembly.

TABLE 3 (continued) BELLEVILLE SPRING HEIGHTS

R

E

-

ASSEMBLY

NOTE:

It is recommended that all internal carbon steel

valve parts and surfaces be coated with light motor oil.

NOTE:

The stems’ packing contact areas

shall be coated with Molybdenum Disul-

fide Anti-Seize Grease

.

1) Body is placed on its inlet

flange, clamped hub or welded

end with the body cavity facing up.

3) Stem is to be oriented

so that tongue flats are

parallel to bore.

2) Stem shall be inserted

through the stem hole

from the body cavity side.

NOTE:

Mark on top of stem should be on

the left of the valve, when looking down on

the stem and facing downstream.

4) Replace stem pack-

ing and gland.

NOTE:

Mark on gland will be on the left of the valve.

5) Install the gland springs with their conical ends

facing each other. Gland springs are hand tight-

ened.

NOTE:

Always coat both ends of gland nuts with a

copper-based anti-seize lubricant to achieve correct

stud tension and corrosion protection.

CAUTION! Only approved ValvTech-

nologies components should be used

in the re-assembled valve.

12-1/8 .760 .800

13-1/4 .790 .830

15-1/4 .890 .930

17-1/4 1.080 1.160

19-1/4 .860 1.020

21-1/4 1.390 1.460