VAL

S

TEAM

ADCA

Produced in accordance with Sound Engineering Practices of the European PED - Pressure Equipment Directive.

IMI P130.08 E 00.20

22

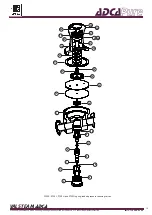

5. Thoroughly clean the inside of the valve body (1) and cover (2).

6.

Place a new O-ring (10), insert a new seat seal (6) into the valve seat (9) and screw

it in place, tightening with the recommended torque – see section 9.4 – Tightening

torques.

7. Disassemble the diaphragm assembly by holding the pusher disk (14) in a vise and

unscrewing the nut (19).

8. Renew the serrated lock washer (20), upper diaphragm (16) and lower diaphragm

(15). For self-relieving regulators replace the O-ring (13).

9.

Clean reusable parts and reassemble the diaphragm assembly (14, 15, 16, 18,

19, 20). Hold the pusher disk (14) in a vise and tighten the nut (19) until the lower

diaphragm (15) just starts to deform.

10.

Place the diaphragm assembly (14, 15, 16, 18, 19, 20) onto the body (1) followed by

the washer (17). Fit the O-ring (32) if the regulator is dome-loaded and adjustment

spring (21) if spring-loaded.

11. Apply a suitable lubricant on the cover (2) thread and screw it into the valve body

(1) tightening with the recommended torque – see section 9.4 – Tightening torques.

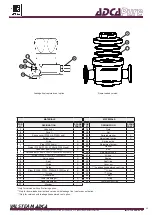

9.3. P130K, P130J, P130H and P130G pressure reducing

valves

9.3.1. Replacing the seat and plug assembly

1. Completely relax the adjustment spring (21) or disconnect loading control pressure

supply. If the valve is removed from the line, fix the valve body (1) in a vise with soft

jaws, with the bottom cover (3) pointing upwards.

2. Unscrew the bottom cover (3) and remove O-ring (4), guide (11), valve spring (8),

plug assembly (5, 6, 7, 12), seat (9) and O-ring (10).

3. Thoroughly clean all surfaces.

4.

Place a new O-ring (10) and valve seat (9) inside the valve body (1) followed by a

new O-ring (4), plug assembly (5, 6, 7, 12) and valve spring (8).

5. Apply a suitable lubricant on the bottom cover (3) thread and insert the guide (11)

inside.

6. Carefully align the guide (11) with the piston (5), tightening the bottom cover (3)

with the recommended torque – see section 9.4 – Tightening torques.

9.3.2. Replacing the diaphragms

1. Completely relax the adjustment spring (21) or disconnect control pressure supply.

If the valve is removed from the line, fix the valve body (1) in a vise with soft jaws,

with the cover (2) pointing upwards.

2. Unscrew the cover (2), remove the O-ring (32) if the regulator is dome-loaded and

adjustment spring (21) if spring-loaded.